A WINCH represents the epitome of self-recovery.

It’s the true essence of a ‘get out of jail free’ card for every genre of 4x4ing; whether it be remote travel, weekend rock-hopping with your mates, competition use, or even with many school pick-up 4x4s – you know, the shiny ones that have every conceivable accessory bolted on like it’s a badge of honour.

A winch is the quintessential must-have accessory that screams to all who will listen that you are a fair-dinkum 4x4er, regardless of how often you’ll really need to use that lump of dead weight bolted to your bullbar.

For those who do use them, a winch provides a huge chunk of security, elevating your chances of getting out of the poo, almost, regardless of depth.

For those who do use them, a winch provides a huge chunk of security, elevating your chances of getting out of the poo, almost, regardless of depth.

So, in true 4X4 Australia form, we have assembled seven of the best electric winches available off the shelves in Australia, for a no-holds tug-o-war.

We have enlisted a test method to ensure total fairness, and we’ve made sure the environment used for each winch remains the same. We’ve taken a gaggle of measurements of each winch while working right up to and beyond their maximum loads, ensuring we could evaluate each winch by the data.

During our testing, we had a couple of minor failures, one smokin’ winch, plus uncovered a flaw many winches exhibit, which may encourage winch makers to redesign that key component.

Plus, of course, we are able to serve prospective customers the perfect information for when it comes time to choosing a winch.

THE CONTENDERS

WE SETTLED on utilising 9500lb (4309kg), or as close as possible, electric winches fitted with synthetic rope from each supplier. This equates to a size winch that most family-orientated 4x4s would expect to use successfully. There are larger, heavier duty winches, but the size we’ve chosen opens up a range perfect for most 4x4s.

For this test, we compared the Sherpa Mustang 9500, TJM Torq Winch 9500, Thunder 9500, Bushranger Seal 9500, and Runva EWX 9500. Also included are the Warn Zeon 10,000 and Warn Magnum 10,000 winches, being the closest size winch available.

Opposite Lock declined, given it was on the verge of changing its complete winch line-up. Ironman 4x4 also declined to be included.

Opposite Lock declined, given it was on the verge of changing its complete winch line-up. Ironman 4x4 also declined to be included.

There are a number of emerging big brand names being imported from various countries, as well as the plethora of el-cheapos, but we simply weren’t interested in those for a number of reasons.

SYSTEMS AND STRATEGIES

IN A TEST as complicated as this, we wanted to ensure the testing method was fair and equal across all products, regardless of how many pulls were required of the winch. Finding the right conditions was paramount. We had to cross off sand dunes because they differ considerably after every single pull. Likewise, with a mud pull and most other surfaces other than hard-packed dirt or gravel.

We trialled steep, dirt hills with constant and ever-changing slopes using my own winch fitted to my Troopy with the handbrake on, and we tried winching dead weights up those same hills.

The problem was that the incline was either too easy or too hard, not to mention the many other technical reasons why it wasn’t an even playing field and therefore unsuitable to help us find the real winner of our test. Enter the ‘sled’.

Anyone that has been to a rural agriculture show will have heard of a Tractor Pull. This is where tractors attempt to pull a sled the furthest distance along a flat, graded, dirt track. The trick to the sled is that as it moves forward along the ground, the weight advances (or slides) from the rear end to the front of the rails, making it harder and harder to slide along the ground as the tractor advances along the track.

Anyone that has been to a rural agriculture show will have heard of a Tractor Pull. This is where tractors attempt to pull a sled the furthest distance along a flat, graded, dirt track. The trick to the sled is that as it moves forward along the ground, the weight advances (or slides) from the rear end to the front of the rails, making it harder and harder to slide along the ground as the tractor advances along the track.

I figured if we replaced the tractor with a winch, we’d get reliable results. All I had to do was source the sled.

Given I could alter the weight on the sled, both on the mechanically geared, moveable tray section as well as the front pad, it proved the ideal method to test the winches. It took half a day of trial runs to find the correct setting for the weights. Eventually we settled on a fixed weight of concrete at the front, combined with the sliding section set in place with two 1000-litre water containers. Nothing would change across the testing for all seven winches in the test.

We tested the pulling force – weight of the concrete and the actual sled, combined with the friction on the ground and the slope we were winching up – and we came up with an overall pulled mass of approximately five tonne. That’s 5000kg pulled by 9500lb (4309kg) rated winches, which would put them to the test, hopefully without destroying the winch.

For dead weight or an anchor point, there was the option of winching from my Troopy and tethering it to a tree, but the risk of chassis damage from twisting or stretching was too much. Instead, we copped a 6.2-tonne telehandler to resist the pulling forces. We hitched a removable winch cradle – to which each winch was bolted – to slide into a hitch receiver on the mammoth telehandler.

For dead weight or an anchor point, there was the option of winching from my Troopy and tethering it to a tree, but the risk of chassis damage from twisting or stretching was too much. Instead, we copped a 6.2-tonne telehandler to resist the pulling forces. We hitched a removable winch cradle – to which each winch was bolted – to slide into a hitch receiver on the mammoth telehandler.

Then we chocked the wheels and jammed the hydraulic blade into mother earth, so it couldn’t move anywhere!

While some winch manufacturers provide a duty cycle, many don’t mention it or just provide the warning “do not exceed duty cycle” without actually saying what the cycle should be – a fat lot of help that is. No wonder many people have no idea they can’t just “keep winching ’til she’s out” and end up damaging the winch.

As suggested by some suppliers, we settled on a duty cycle of 60 seconds constant winching, followed by 10 minutes cool down, 60 seconds constant winching, 10 minutes cool down. We repeated this process until each winch had pulled as close to 20 metres as possible.

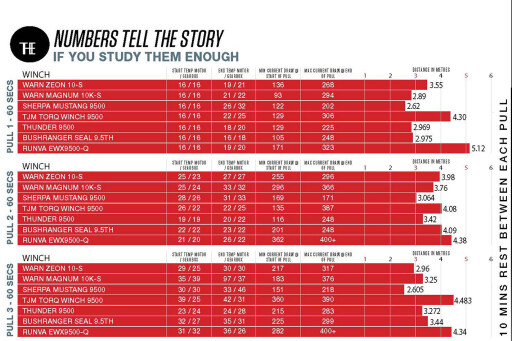

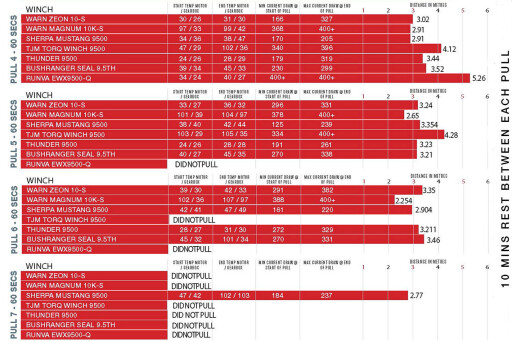

At the start and end of each 60-second winching period, we recorded gearbox and motor temperatures with a non-contact thermal gun, minimum and maximum amperage draw with a clamp meter, as well as distance pulled with an electronic distance measurer – to aid in calculating winch speeds for each 60-second session as well as an overall speed in metres per minute.

At the start and end of each 60-second winching period, we recorded gearbox and motor temperatures with a non-contact thermal gun, minimum and maximum amperage draw with a clamp meter, as well as distance pulled with an electronic distance measurer – to aid in calculating winch speeds for each 60-second session as well as an overall speed in metres per minute.

All of these measured figures allowed us to monitor winch performance in real time while keeping an ‘ear’ on the winches to know how close to stalling and how easy each was tackling the huge loads of the sled. With this method, there could be no denying which winch pulled fastest, furthest, consumed the most power, or got the hottest.

There is no reason to winch to destruction to test a winch; that is simply not how a winch should be treated in real life. Setting up the correct weights to be hauled, with even, fair and repeatable conditions is the perfect way to test a winch and a great way to separate quality from crap.

SAFETY

WINCHING is dangerous. We’ll repeat that… winching is bloody dangerous.

While we always adhere to taking as many safety precautions as possible in a real-life winch situation, this testing posed additional safety threats given we needed to be close to the winch to take motor current draw and temperature readings.

I knocked up two walls of 12mm sheets of ply with relevant slots cut out to thread the winch rope through. The walls were angled such that if a rope broke and flicked back at us, it would be blocked and deflected up and away from us.

I knocked up two walls of 12mm sheets of ply with relevant slots cut out to thread the winch rope through. The walls were angled such that if a rope broke and flicked back at us, it would be blocked and deflected up and away from us.

Instead of a simple air brake hanging over the winch rope, we’ve attached a dedicated, weighted sliding dampener close to the hook end and tied it back to the sled. If anything were to break, the dampener would stop the heavy hook and arrest the dangerous rope re-coil. As a side note, synthetic rope is much safer than wire rope if it should snap under strain, but we weren’t taking any chances.

POWER

12-VOLT winches churn through a heap of power. Generally, your winch is hooked up to your main starter battery which is charged via your alternator while winching. If that battery is anything less than 100 per cent, a winch’s ability to pull is diminished. Given we were attempting longer than usual winch pulls, as well as multiple pulls, there was no way a standard battery-in-vehicle set-up would cope.

Having had past experience with a mob who, along with their father, manufacture the venerable Outback Battery Chargers via their company Christie Engineering, I figured they would be my saviour for battery charging. They kindly loaned us a top-of-the-line 120amp petrol-powered battery charger.

Australian manufacturer Century Batteries provided four 105amp deep-cycle AGM units, which were wired up in parallel with high grade battery cabling. This huge battery bank and wiring system remains a 12-volt system, but the Amp hours were bumped up to a huge 420amps (4x105amps) to ensure we had plenty of grunt in reserve.

Australian manufacturer Century Batteries provided four 105amp deep-cycle AGM units, which were wired up in parallel with high grade battery cabling. This huge battery bank and wiring system remains a 12-volt system, but the Amp hours were bumped up to a huge 420amps (4x105amps) to ensure we had plenty of grunt in reserve.

We ran the Outback Battery Charger during winching, as well as the 10-minute winch cool periods. This is one part of the test that is not ‘real life’ given we mostly only have one battery to run a winch from, but, given our want to test the winch to maximum capacity, we bulked up on the amperage power to be sure all went as planned.

THE SAME BUT DIFFERENT

LOOKING at the specs of each winch, there are only a few technical differences that can make a difference to a winch’s ability to perform: motor horsepower, final gear ratios, drum diameter and amperage draw.

Let’s get one thing straight, a fast winch is not necessarily the best winch! It may be fast in trying to extract your bogged 4x4 from danger in the beginning, but if it can’t maintain that speed due to high current draw (flattening your vehicle battery), cooks your winch thanks to high motor temps, or stalls the overloaded vehicle via high gearing, then what’s the point being fast for a short period?

You want a winch that gets the job done, even if it takes a bit more time. So for the purpose of this test, we’ve ignored that quoted-but-useless specification.

When it comes to the horsepower of the motor, generally, the higher the better. It’s like a larger cubic capacity vehicle engine develops more torque than a small capacity version – all else being equal. But, more torque doesn’t necessarily mean faster.

In gearing ratios, the lower the final gear ratio number (eg. 150:1 compared to 268:1) the faster the winch drum will spin resulting in a higher line speed. The motor (or gears) turn 150 times to turn the drum one full revolution, compared to the lower-geared version which has the motor turning 268 times to turn the drum once. So, the higher the number, the slower it works; and the lower the number, the faster it works.

In gearing ratios, the lower the final gear ratio number (eg. 150:1 compared to 268:1) the faster the winch drum will spin resulting in a higher line speed. The motor (or gears) turn 150 times to turn the drum one full revolution, compared to the lower-geared version which has the motor turning 268 times to turn the drum once. So, the higher the number, the slower it works; and the lower the number, the faster it works.

However, the faster the ratio (the smaller the number), the harder the winch has to work and the more likely it is for the whole shebang to stall. Just like labouring your 10-speed pushie up a hill, if you leave it in the highest gear, your legs won’t be able to supply the power needed to keep the pedals moving, so you stop and flop.

A lower winch gear ratio (higher number) is slower, but will get the job done easier… eventually. It’s the old story of the Tortoise and the Hare – we all know how that ended.

As far as amperage draw goes, the more electronic power that little 12-volt motor can consume, the faster it will perform, but the hotter it will get and the sooner it will melt or burn something beyond further use.

Keeping motor and gearbox temperatures down can only be done via short winching times and long rest times – the correct duty cycle – or perhaps, to a lesser extent, fluting or heat soaks built into the winch casing to help dissipate heat. But once the whole casing gets overly hot, there’s little you can do to cool it all down, other than rest.

Keeping motor and gearbox temperatures down can only be done via short winching times and long rest times – the correct duty cycle – or perhaps, to a lesser extent, fluting or heat soaks built into the winch casing to help dissipate heat. But once the whole casing gets overly hot, there’s little you can do to cool it all down, other than rest.

An often forgotten specification that directly leads to winch ability, or lack thereof, is the drum diameter. The larger the drum diameter, the faster the gearing (but more load will be placed on the winch). Conversely, the smaller the diameter, the slower the gearing, making winching easier.

It really is impossible for average humans (like me) to calculate the exact final pulling power of any winch when all variables are taken into account.

DRUM LAYERS, SURFACE RESISTANCE, DEPTH AND SLOPE

ONE of the common misconceptions regarding winches is that the maximum rated winch capacity is available any time the winch is hooked up. Unfortunately, this is false. Winch capacity is in fact determined by the number of layers of cable wrapped on the winch drum.

While line pull per layer is an often quoted specification, given an empty winch drum affords the smallest diameter and a full drum the largest, it’s easy to presume that as each layer of rope rolls onto the drum, the winching effort increases proportionally.

All winches are maximum rated with an empty drum, while their (mathematical) rating drops dramatically to almost half when full. Yep, a 9500lb winch is only rated at 9500lb when the drum is on its first layer, yet is only (mathematically) rated at about half that (about 4500 to 5500lb) with four or five rope layers rolled onto the drum.

Theoretically this is correct, but in reality it doesn’t exactly work like the pretty diagrams (that are bandied about with nice neat layers of rope) suggest.

Theoretically this is correct, but in reality it doesn’t exactly work like the pretty diagrams (that are bandied about with nice neat layers of rope) suggest.

Synthetic rope is somewhat flexible (can be distorted and flattened) and the rolls can never be totally pushed up hard against each other as the winch drum rolls in. We found the rope would either mesh into the previous roll, providing similar drum diameters (ratios); or would bunch up on one side for a few rolls, effectively raising drum diameter and ratios.

While you can, at times, help to guide the rope in for a neat roll by pulling the rope sideways from the winch body, you are putting yourself directly in the line of fire if something fails and flings back.

The neater the rope is kept while pulling in, and the straighter the pull is in line with the vehicle, the better the chances are of keeping an even drum roll.

Ideally, any winch pulling a stuck vehicle should be using the first or second roll on the drum to return the best load ratings and maximum pulling power.

Ideally, any winch pulling a stuck vehicle should be using the first or second roll on the drum to return the best load ratings and maximum pulling power.

Unfortunately, this is not always practical in real life; your tree or winch anchor point will (almost) never be perfectly positioned, so you’ve just gotta use what you have available, or use a double line pull to get more rope of the drum to start with.

Every winching exercise must also consider surface resistance, slope and depth. Resistance of the ground you are stuck in; deep fluffy sand, gloopy wet mud and rocky ledges are all going to add higher winching resistances than a loose, gravelly track. So too will any gradient above dead level.

The depth of the poo you are stuck in will sky rocket your winch’s inability to do its job – the deeper the shit you’re stuck in, the more likely you are to remain stuck in said shit.

WIRELESS VERSES WIRED

SOME winches tested came with both wired and wireless remote controls. Wireless is a great option in the right predicament, which allows the user to stand or sit (almost) anywhere to control the winch, provided it’s safe to do so. In our experience, as great as wireless remotes are, they have a time delay or lag from when you start and stop the winching button or command.

So, when you button off the power, often the winch will run a little longer, which we find a little disconcerting if trying to winch precisely. Wired winch controllers generally don’t exhibit this annoyance, tending to switch on and off much more precisely. We used the wired options on all winches as tested.

So, when you button off the power, often the winch will run a little longer, which we find a little disconcerting if trying to winch precisely. Wired winch controllers generally don’t exhibit this annoyance, tending to switch on and off much more precisely. We used the wired options on all winches as tested.

WHICH WINCH?

EVERYONE wants to know a single winner, but while we’re happy to give the thumbs up to one winch here, there’s nothing to suggest all the other winches won’t do the job intended.

It’s great to see that every winch on test passed our rigorous test procedure, which is a testament to the quality that’s available if you buy known brands of equipment.

While the overall winner combines the data we recorded with price, inclusions, motor horsepower rating and gearing ratios, the second place recipient sees very different specifications combined with vastly different recorded readings to achieve a similar end result. This proves how different two winches can be, while still offering an excellent outcome at the end of the day.

Also, given both the winner and runner-up suck awful high currents, you’d need to be sure your battery system is in good condition. Wading through the collected data table, you’ll find some other winches consumed far less amps, so perhaps one of these winches would better suit your set-up.

Also, given both the winner and runner-up suck awful high currents, you’d need to be sure your battery system is in good condition. Wading through the collected data table, you’ll find some other winches consumed far less amps, so perhaps one of these winches would better suit your set-up.

So, drum roll please… the winner of our ultimate ‘Pull Power’ winch test is the Runva EWX 9500 winch, while the TJM Torq Winch takes out a very close second place. We’d be happy to bolt either of these winches to our bullbars, and we’re positive both would get us out of strife in almost any off-road situation.

Congratulations to both brands and thanks to all who have participated in this world-first 12-volt winch shoot-out.

THANKS

THERE is absolutely no way we could have completed this test without a few sets of willing hands to help with time, expertise and equipment. Special thanks must go out to:

Todd from Momentum 4x4 in Wauchope, NSW, for lending us a hand and bringing your 4x4 knowledge;

the team at Maitland Steam & Antique Machinery Association, for their willingness to supply people, the sled and other machinery;

Century Batteries, for supplying four deep-cycle 105ah batteries to form our huge battery bank of power;

Century Batteries, for supplying four deep-cycle 105ah batteries to form our huge battery bank of power;

Christie Engineering, for the loan of its 120amp petrol-powered battery charger to keep our battery bank in tip-top condition; and a huge thanks to the manufacturers and suppliers of the winches.

COMMENTS