We’ve got it good these days. Just one generation ago your choice of 4x4 was limited, and it was likely rudimentary, agricultural, underpowered and underwhelming.

Despite the often-romanticised ideas of rugged simplicity, you’d be doing well to find a 4x4 that could pull the skin off a custard, and you’d probably be locked up in a looney bin if you expected one that could ride well on-road and still manage to work well off-road.

These days 4x4s have surged forward in leaps and bounds; power, ride quality and useful off-road features are the standard, but they’re still mass-marketed vehicles, designed for everyone, not anyone. If your needs fall outside the scope of the manufacturer’s ideas then the aftermarket is your source of salvation.

Enter Superior Engineering. This company has been slowly but surely redesigning every aspect of various 4x4 models to make them perform better. From the Superior’s early radius arm to its later high-tech electronically controlled shocks, it has been making 4x4s do things vehicle manufacturers never thought possible.

With the introduction of Superior Engineering’s coil-conversion kits, the company is essentially re-engineering vehicles to how they should have come from the factory. If you’ve ever fantasised about what a HiLux Raptor competitor would be, Superior has the answers.

But what exactly goes into its coil conversion kits, what are the pros and cons, and how much is it going to hurt the hip pocket to build a better HiLux than Toyota can? We caught up with Sam Turnbull, the General Manager at Superior Engineering to find out.

Jack of all trades

Forget the awkward stage in the 80s and 90s when vehicles came fitted with torsion bar springs.

These days, your 4x4 either has coils all around or coil front-end and leaf spring rear combination. Manufacturers tend to install leaf springs in the back of anything designed for load carrying, while four-wheel drivers tend to opt for coil springs. But what exactly is it that makes coil springs better for off-road use, and why is no one swapping out coil springs for leaf springs?

The answer is relatively simple: cost, complexity and versatility. Let us explain.

Leaf springs are a jack-of-all-trades setup. They physically locate the axle front to rear, side to side, and provide the spring rate and thus load carrying capacity. They also resist the axle twisting, but more on that later.

Coil springs, by comparison, just handle load carrying, so your axle will still require some kind of locating system. These are typically in the form of four forward-facing control arms to prevent axle twisting and locate the diff fore and aft, with a Panhard rod controlling side-to-side movement.

So it’s obvious how much simpler a leaf spring setup is than coil springs, but that comes at a cost. The leaf spring rate doesn’t just define how the 4x4 rides, but how well it holds the axle in place, and the two are tied together. Soften the spring to flex better and you’ll likely get axle wrap that can lead to your rig bucking and bouncing in terrain that a coil spring rig can effortlessly drive over.

Leaf springs are also heavy, cumbersome and more slowly than lighter-weight coil springs. That means side by side, in the case of coil and leaf springs both rated for +300kg, the coil spring will be able to cycle faster, absorbing more bumps in the road and allowing greater articulation and axle control off-road.

This is why manufacturers go to the extra expense of fitting coil springs all-round to more off-road focused models, while jack-of-all-trades utes get jack-of-all-trades leaf springs. If you’re building your rig for a purpose, and that includes either better articulation off-road or better ride quality on-road, then it’s easy to see why so many people are opting to up-spec to Superior Engineering’s coil conversion kits.

Whats in the box?

When you unbox one of Superior Engineering’s conversion kits, you’re met with a carefully curated set of components designed to transform your rig’s suspension.

The core of the kit focuses on a whole heap of computer-designed bracketry intended to result in a near-factory finish, transforming your chassis from something that accepts leaf springs to something that accepts a coil and link arrangement.

The kits themselves are a weld-in design rather than the easier-to-install but not as rugged bolt-in designs, Superior favouring a little extra effort at the start for more peace of mind down the track. Included are a set of inner and outer chassis braces to ensure the chassis can handle the new loads and to provide mounting points for the new links.

You’ll score 40mm OD fixed lower control arms and adjustable uppers so you can dial in your pinion angle to suit vehicle ride height, as well as an adjustable Panhard rod to aid in wheel alignment.

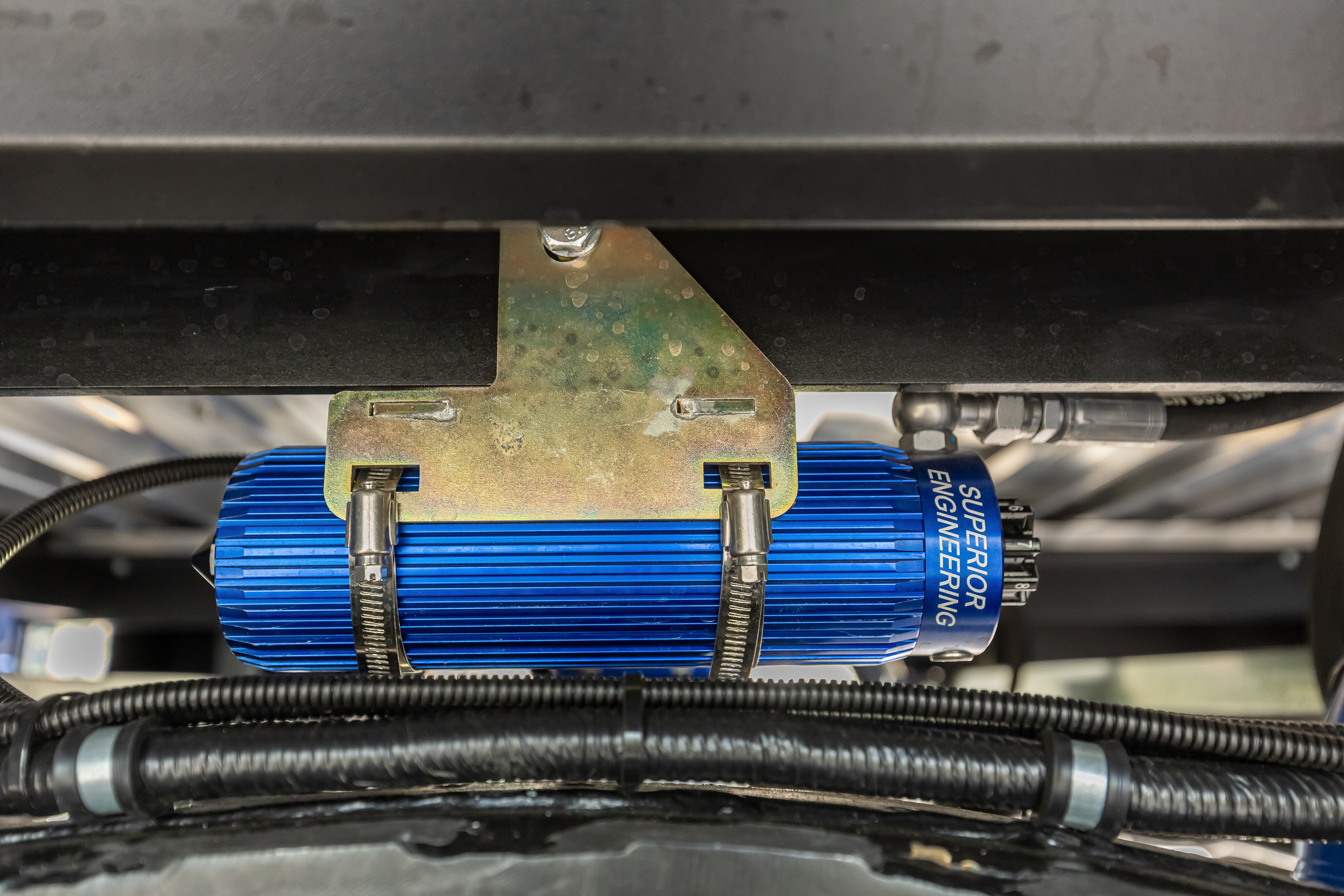

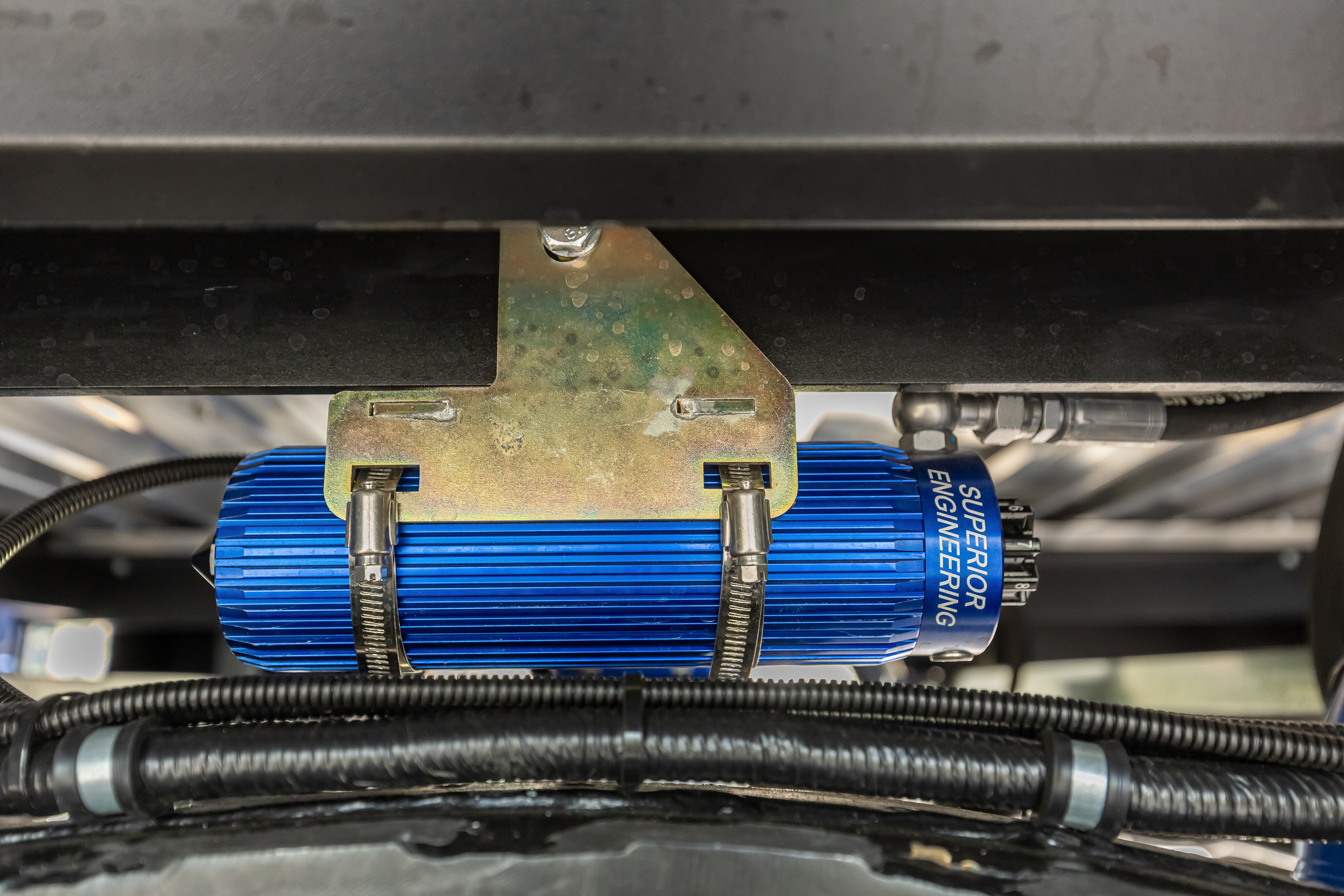

The Superior package will be familiar to anyone who’s worked on the popular five-link style suspension setups in LandCruisers and Patrols. You don’t get coils in the basic kits – Superior Engineering offers bespoke options to suit your needs rather than an off-the-shelf spring rate and height for everyone – although the kit to lifts up to five inches lift depending on the vehicle model, and it comes with lower spring mounts and a beefier upper coil mount.

There are shock mounts designed to suit Patrol shocks, providing a huge choice, and again the base kit comes with just the hardware so you can up-spec to shocks of your choice.

Depending on the model you’re installing the kit into, it can be supplied with extras such as sway bars and mounts, handbrake relocation bracketry, and upgraded diff housings to suit vehicles with GVM upgrades.

Can I get one for my rig?

The bad news is, the range of models the coil conversion kits are suited to is quite limited at the moment, but the good news is the models they do suit are popular on the tracks.

Convenient, eh? If you’ve got a 76 or 79 LandCruiser parked up in the shed you’re in luck. This is without a doubt the most looked-after model in Superior Engineering’s line-up and arguably the one that drove production, as these models are screaming for a more supple suspension system for touring comfort and articulation on the tracks.

Coming in second place it’s no surprise to see both the 2015+ N80 HiLux and the PX1/2/3 Ranger/BT50 platform well looked after… with mild to wild kits. In addition, Superior has kits in the works for the D-Max, N70 HiLux, Holden Colorado, Mitsubishi ML/MN/MQ Triton, and the old faithful leaf-spring GU ute.

Before diving in, check with Superior for your specific make and model. There’s detailed information on the company’s website so you can confirm whether your 4x4 rig can join the coil-spring revolution or if you’ll have to wait a little longer.

What's involved?

Taking a grinder and a welder to any vehicle, let alone a brand-spanking-new dual-cab ute can be a daunting prospect.

In years gone by, to coil-convert a leaf-spring setup you’d need to cut bracketry off a donor vehicle (typically an 80 or 105 Series LandCruiser) and then graft it onto your vehicle using a tape measure and a whole lot of praying.

Thankfully, the Superior kits are a fair bit simpler these days complete with step-by-step instructions. Step one is always going to be jacking your rig up and stripping off the old setup. Depending on your make and model you may need to transfer the diff centre and hubs over onto a new axle housing, or you may simply need to remove the leaf spring bracketry from the factory housing to reuse that.

The new mounts and chassis plates have all been designed to pick up OEM holes on the chassis so near-enough fall into place to be welded right on, and this is the same with any bracketry fitted to the housing for picking up coil, shock and link mounts.

From here a lick of paint, fitting up of the links, coils and shocks, as well as any other ancillary kit like sway bars, brake lines and ABS wiring, and you’re ready to get it aligned and legal. All in, with a qualified boilermaker or welder on the trigger, the whole affair can easily be knocked over in a weekend.

Any way you like it

The whole point of the coil-conversion kits is that one size doesn’t fit all, so it’s not surprising to see Superior doesn’t just offer a one-size-fits-all kit regardless of your needs.

Instead it offers a range of optional upgrades that allow you to fine-tune your suspension system to match your specific requirements.

Among the popular upgrades are adjustable shock absorbers, which grant you the flexibility to tweak damper settings; this can be invaluable when transitioning between different terrains or when carrying varying loads.

For those who crave the ultimate in off-road performance, consider investing in adjustable remote reservoir shocks; these shocks offer increased oil capacity, enhancing their ability to dissipate heat and maintain consistent performance, as well as giving you the flexibility to dial in exactly how you want your rig to perform.

Depending on your make and model, there are also GVM upgrades, packages to suit front and rear suspensions, as well as the wild X-Track kit which adds 11-inches of wheel track to the HiLux platform to transform it into a serious Raptor competitor.

The fine print

While the advantages of coil conversions are abundant, it’s essential to acknowledge that no modification is without its trade-offs.

One potential drawback of a coil conversion, particularly when performed by inexperienced hands, can be an imbalance between front and rear suspension behaviour. Picture a marathon runner who wakes up one day and decides to train the living daylights out of their right leg, leaving the left one to keep up.

Slotting in a top-tier, uber-flexible coil suspension in the rear of your rig with a janky old eBay lift up front will give you some epic Instagram flex photos, but the ride, handling and stability on- and off-road will be questionable at best.

If you’re getting fancy with the rear, you’ll need to get fancy with the front end too. It’s not a one-size-fits-all affair so you’ll need to spend a little time on the phone with Superior Engineering, running through your exact needs and uses to ensure you get the right combination.

Of course, there’s the elephant in the room too with cost. For a straight out-of-the-box weld-in coil conversion you’re looking at around $6-7k supply only with basic shocks and coils.

If you want to up-spec to remote reservoir shocks front and rear, as well as any other accessories to give you a completely balanced ride, it will typically be around the $10-$16k mark for an IFS ute depending on any GVM upgrades and the shock specification. In a live-axle front and rear rig, cost can range up to and over the $30k mark due to the complexity and extent of components required.

Lastly, it’s essential to remember that modifying your 4x4 may have implications for your vehicle’s legality. Depending on the process you’re following, there’ll be some cost in having your rig signed off for road use, although Superior Engineering can help guide you through the process depending on the state your vehicle is registered in.

COMMENTS