IF YOU have a penchant for perilous tracks that most of the population steers well clear of, then you’ll need to guarantee drive is delivered effectively to all four wheels. The only way to ensure this is with a pair of front and rear locking differentials.

When driving off-road, a differential will always send power to the wheel with least resistance; so if a 4x4 loses traction (in the air, stuck in mud, etc.) the wheel with the least traction will spin ineffectively.

Locking the diffs prevents this by sending equal drive to both wheels on an axis, regardless of terrain or traction, so with front and rear diff lockers (either selectable or automatic) you’ll be able to crawl through most obstacles with little or no wheelspin.

“Lockers are a great investment, as they dramatically improve the vehicle’s capabilities by giving the owner the ability to lock or unlock the differentials as necessary and capture 100 per cent of the available torque and distribute it equally to both ends of the axle,” Harrop’s design engineer, Sebastian Civitarese, told us. “This enables the driver to keep momentum when off-road and safely navigate harsh terrain without losing traction. It’s equally beneficial for the average tourer or when towing on slippery surfaces like boat ramps.

“Ultimately, lockers mitigate the loss of traction,” he said.

Locked up

A COMMON misconception by many 4WD pundits is that by shifting a vehicle into ‘4WD’, power will be sent to all four wheels at all times. However, in certain scenarios a standard vehicle with open differentials will only deliver drive to the easiest wheel to spin on any given axle, which will be the one in a mud hole or up in the air.

“A locker allows you to have full power to both wheels, even when one is off the ground,” said Terrain Tamer parts interpreter, Charlie Dunbar. “So when that wheel lands, you have movement already, allowing you to gain traction and get out of a bad spot.”

ARB’s brand marketing manager, Mark Berger, added: “With a differential locker, you can lock the differential to stop it from spinning the left and right wheel of an axle independently of each other, forcing both wheels to spin at the same rate irrespective of which wheel has traction and which one doesn’t.”

.jpg )

Installing a set of diff lockers and being able to lock and unlock the diffs when required increases a vehicle’s off-road abilities exponentially, with 100 per cent of the available torque able to be equally distributed to both ends of an axle.

As Justin Hettrick, TJM’s suspension and drivetrain product manager, explained, a diff locker provides instant traction: “The off-road ability of almost any 4x4 vehicle is doubled. A locker can be the device that makes you traverse terrain you never thought you would be able to.”

Centre Diff

A CENTRE differential, as the name implies, is positioned – in all-wheel drive and constant 4WD models, like the popular LandCruiser 200 Series wagon – between the front and rear differential. Unlike front and rear differentials, though, a centre diff will split power 50/50 front to rear instead of side to side of each axle.

.jpg )

A centre diff lock is essential to ensure drive to both the front and rear axles; although, diff locks front and rear are still required to spread drive evenly from side to side.

“Vehicles with a centre diff (and no lockers) can deliver drive to any of the four wheels of the vehicle, but the power will still only be delivered to one wheel and it will still be the wheel with the least traction,” explained Berger.

Front & Rear?

OPTING for either a front or rear locker ultimately depends on the type of vehicle and the equipment already installed. For example, some vehicles have a limited-slip differential (LSD) from factory, and therefore it may be a wise decision to opt for a locker in the front and leave the rear unchanged. For vehicles with open differentials, a rear locker is by far the more popular choice, as it’s more suitable to a diverse range of off-roading situations.

“If the vehicle only has open differentials we typically recommend a rear, which will be more effective when off-road hill climbing,” said Sebastian Civitarese. “If the vehicle has a factory LSD in the rear, it is a much better solution to install an ELocker in the front and retain the LSD in the rear.”

.jpg )

According to Mark Berger, rear lockers will give you best bang for buck, as the rear suspension will flex more and keep in contact with the ground, keeping that all-important momentum going. However, front lockers aren’t without their benefits, as Berger explained: “A front locker is perfect for climbing hills or pulling you through the last bit of a bog-hole or over a rock ledge. But front lockers can also restrict your steering ability when weight is over the front axle (i.e. flat ground and downhill), so you have to be careful when you use them.”

A third – and more effective – option is to install lockers on both the front and rear differentials.

“Why can’t we just have both?” asked Berger. “A locker on one axle will improve your four-wheel drive from 50 per cent drive to 75 per cent drive, while installing lockers on both differentials will provide you with 100 per cent drive.”

Why use quality lockers?

CONSIDERING a locker is an essential tool for those chasing remote, hard-to-reach campsites, it’s essential not to ‘cheap out’ and get a sub-standard unit that’ll leave you wishing you forked out more coin to a reputable brand. Surf the web and you’ll quickly find an abundance of products from dubious websites, but do your research and you’ll find that buying from a well-known, respected company makes a helluva lot more sense.

“A locker isn’t a component you want to skimp out on and settle for an inferior brand or quality,” said Sebastian Civitarese. “If something goes wrong out on the track, you have the potential to be left stranded.

“The cost of pulling a diff and repairing problems will quickly exceed the initial investment of purchasing a high-quality locker.”

ARB’s Mark Berger couldn’t agree more: “At the end of the day, a locker is an important mechanical component of your vehicle’s driveline, and as such it would serve 4WD owners well to ensure they respect the vehicle which they rely on to safely and reliably get them where they are going and back.

“As a technical and mechanical component, removal and installation can be both costly and time consuming, so it is worth purchasing a product that is both more likely to last and be supported by the manufacturer and installer.

“Quality, proven manufacturers are held to high industry standards with thousands of customer’s expectations worldwide to look after, trust in them that they will support their product and their customers.”

As always, the trusted brands will offer multi-year warranties: TJM and ARB, for example, both offer five-year warranties for their respective Pro Locker and Air Locker, and Harrop and Terrain Tamer offer three years for the ELocker.

.jpg )

“Substandard lockers just aren’t made with the same high-quality materials, they haven’t undergone the same research, development and engineering, and haven’t had the same testing done to create a quality end product,” explained Charlie Dunbar. “Breakage is so common in substandard lockers, and, of course, they can cause breakage to other parts.”

Selectable v Automatic locker

Control is the main difference between a selectable and an automatic locker; you have control with a selectable locker and you don’t have control with an automatic locker. Choosing when to lock and unlock the diffs is important, as it can alleviate the stress on a vehicle’s drivetrain components.

“With an automatic locker, the diffs are always locked until enough cornering force is applied to release the locking mechanism from the diff,” said ARB’s Mark Berger. “The design of many automatic lockers can become the culprit of interesting on-road behaviour, as they lock and unlock and can lead to unnecessary wear on the vehicle’s driveline and tyres.”

Limitations of LSD

It’s common for showroom-stock vehicles to have an open diff up front and a limited-slip diff at the rear. The job of a limited-slip differential is to direct power (or drive) away from the wheel with less traction and send it toward the opposite wheel on the same axle.

“LSDs have long been considered a great option in the rear of many 4WDs, but they do have their limitations,” said Berger. “LSDs operate not too dissimilar to an automatic locker, where an amount of cornering force is required to release the resistance for the diff to spin freely and deliver drive to the wheel with the least traction.”

.jpg )

An LSD can never be 100 per cent locked and comes with limitations.

“LSDs by design are built from components such as clutch plates, which are prone to wear, and given they are being operated every time you drive the vehicle, the diff will progressively deteriorate in its functionality, becoming less and less effective,” added Berger.

Charlie Dunbar from Terrain Tamer added: “An LSD can’t supply full power to the wheel that needs it, and will always give part of it to the wheel with no traction.”

Pros & Cons: Selectable Lockers

PROS

• Reduces wear on vehicle components

• Quieter operation

• Instant traction

• Can be turned on and off

• Compressed air on-board (with air lockers)

• Can lock one axle or both axles independently (when running front and rear lockers)

CONS

• More expensive

• Ongoing maintenance (air lines/wiring)

Pros & Cons: Automatic Lockers

PROS

• Driver doesn’t need to lock/unlock diff

• Cheaper alternative

• Purely mechanical (no air lines or wires)

CONS

• Driver has no control on lock options

• Noisier than selectable lockers

• Can affect vehicle’s drive characteristics

• Can increase wear on driveline components and tyres

• Harder to steer until point of disengagement

Types of Lockers

ELockers

THE ELOCKER is a selectable locker, but it differs from air-activated lockers (TJM’s Pro Locker and ARB’s Air Locker) as it uses an electrical magnet instead; which rotates the ramp plate to engage the lock pins and the locking plate which locks the side gear into the housing. When disengaging, the magnet is released and the locking plate returns to its unlocked position by the means of a return spring.

“ELockers are a fairly simple design in terms of installation,” said Dunbar. “There’s also the benefit of no air lines to run, or compressor to install or purchase.”

The ELocker is designed and manufactured in Australia, with the unit CNC-precision machined and featuring precision-forged and heat-treated gears. The internal gears from Eaton are specifically intended for heavy-duty application and provide improved strength and durability over standard-cut gears.

.jpg )

“The patented four-pinion electronic locker systems are then made in Australia and operate manually using an electromagnet powered by the vehicle’s battery,” added Dunbar.

Another benefit of the ELocker is that it requires no external module, compressor or hoses; it’s simply click and forget. This locking mechanism is trusted by OEMs globally – take the Chevy Colorado ZR2, for example, which features the technology in both the front and rear differential, further validating the design’s credentials and durability.

TJM Pro Locker

The TJM Pro Locker is manufactured from high-strength SG Iron, and the pinion gears are thicker than the OE (Original Equipment) gears. The flange cap assembly is extra thick to utilise longer crown wheel bolts, again, to increase strength.

Utilising compressed air, when the locker is activated the internal selector ring will engage the lock ring. Once the Pro Locker is engaged it forms a solid link between the carrier and side gears. The differential is now locked and will deliver 50/50 drive to both wheels across an axle.

.jpg )

A uniquely designed actuator works like a motor piston. The fork sits on top of the selector ring guiding it across when engaging or disengaging. This hardened selector ring connects to the lock ring via four metal posts. The hardened lock ring shares the forces internally and externally, increasing its locking strength.

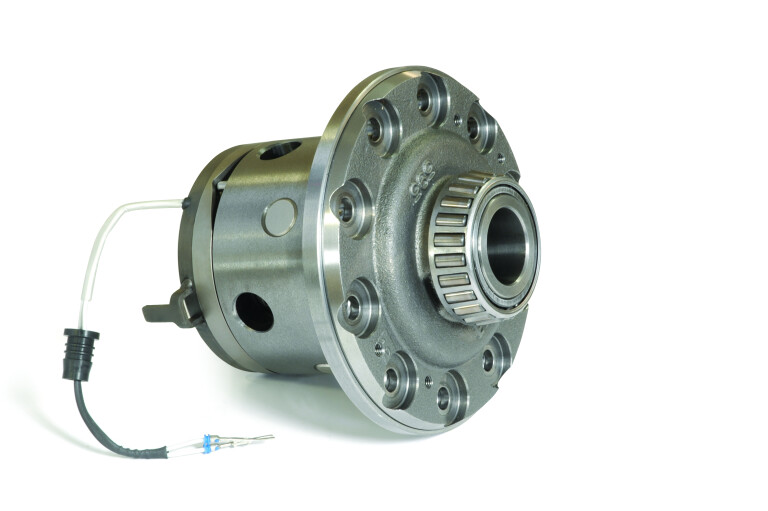

ARB Air Locker

ARB’s selectable Air Locker is installed within the vehicle’s current differential housing and replaces everything except the crown wheel and pinion with new upgraded components for extra durability.

“The basis of the design is that compressed air is supplied from the onboard compressor, forcing an internal locking ring against the spider gears,” explained Mark Berger.

.jpg )

The Air Locker has four spider gears, which are the components that allow the differential to direct the drive to either the left or right wheel.

“The locking rings lock the spider gears against the housing, which prevents differential action and therefore delivers drive equally to the left and right wheels on the axle,” he said. “When the Air Locker is switched off, the air pressure is released and the internal gears are able to spin freely again allowing the differential to do its job.”

.jpg )

A significant benefit of an ARB Air Locker is that it can be engaged at any speed – unlike an ELocker – so drivers can flick them on the moment they need them, without stopping.

With more than 35 years of experience, ARB says it utilises in-house, highly automated CNC machines that excel at repeatedly producing tight tolerances and precision form that is scrutinised constantly through the aid of programmable robotic measurement.

Automatic Lockers

Brands like Lokka manufacture lockers that don’t require manual operation.

“Think of Lokka as an alternative set of planetary gears,” the company explains. “When factory gears operate or move, so will the Lokka gears. The difference is, the Lokka gears start from a locked position, whereas normal gears are free-spinning.

“The Lokka mechanism allows a wheel to turn faster than the speed the differential is driving it (differential action), but never allows a wheel to turn slower than the rotational speed the differential and engine is turning it (traction). Thus a wheel cannot ever stop turning if the engine is driving it, but in a corner it can be forced to actually turn faster. Unlike a normal differential the engine can never drive one wheel faster than the other.”

COMMENTS