YOU HAVE to admire the cooling systems on modern four-wheel drives.

Think about it: you’re chugging away on a loose, sandy track on Fraser Island, 18lb in the bagged-out tyres, the turbo boosting pretty much constantly, an ambient of 35°-plus, bugger-all airflow and the kids screaming for the air-con to be running flat chat. And yet that little red needle on the temp gauge doesn’t budge.

Miraculous, when you think about it. But there are still times when a replacement radiator is suddenly on your shopping list.

Maybe you’ve upgraded the engine for more power and, therefore, more heat. Maybe you’ve fitted a different powerplant and none of the plumbing lines up. Maybe your vehicle is older with a less effective cooling system or one that’s simply worn out. Hell, maybe you just made it home to find a dirty great stick has gone through the core.

Maybe you’ve upgraded the engine for more power and, therefore, more heat. Maybe you’ve fitted a different powerplant and none of the plumbing lines up. Maybe your vehicle is older with a less effective cooling system or one that’s simply worn out. Hell, maybe you just made it home to find a dirty great stick has gone through the core.

Whatever the reasons, a replacement is sometimes the only fix. But, like anything else in this world, it’s not as simple as that. You have choices, you see.

You can stick with the standard Original Equipment (OE) unit designed for your make and model, or you can go aftermarket in the search for even better cooling performance or to get the level of cooling your new setup demands.

We’re often told that OE parts are best for fit and function, and there’s no problem with that logic. In fact, given that the original radiator in your vehicle probably gave years of fault-free service, it stands to reason that another just like it will do the same. We have no problems with that, and provided you haven’t made changes to the rig that will increase its heat production (or altered the air-flow), you’re on pretty solid ground with an OE radiator.

Carmakers are very careful with the reputation of their genuine replacement parts, too, so you’re unlikely to find that the new part is of any less quality than the unit the car was born with.

Carmakers are very careful with the reputation of their genuine replacement parts, too, so you’re unlikely to find that the new part is of any less quality than the unit the car was born with.

Toyota Australia confirmed for us that the people who make its OE radiators are the same folks who make the genuine replacement units. But that doesn’t rule out going with an OE-style radiator of equal or better quality that just happens to be made by somebody else. Which is where outfits like Terrain Tamer come in.

Terrain Tamer recently entered the replacement-radiator sector with a line-up of units that it says fit just like an OE replacement, but are even tougher. Terrain Tamer’s Brent Hutchinson says the range is designed to work as a drop-in replacement for the OE radiator, so everything lines up and fits properly. But, he says, there are also performance and durability bonuses over an OE unit.

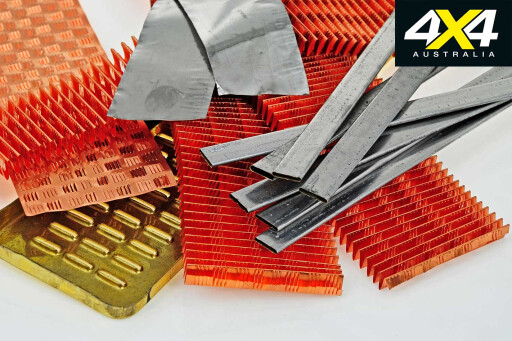

“Our radiators have roughly eight per cent more cooling capacity, which we achieve through a higher fin count (which equates to greater cross-section). All our top and bottom tanks are alloy with stainless steel brackets, but the added strength really comes from the construction which is fully pressed rather than welded,” said Brent.

“At the moment our range is quite small, but we’ll be expanding it over time. The 80 Series Land Cruiser is probably our next part number. But all of our units use the standard hoses, mounting points and shrouds, so they’re a straight drop-in.”

Your other option is to go aftermarket and go big. One of this country’s best-known radiator specialists is Melbourne-based Aussie Desert Coolers, headed-up by all-round petrol-head Norm Handinge.

Your other option is to go aftermarket and go big. One of this country’s best-known radiator specialists is Melbourne-based Aussie Desert Coolers, headed-up by all-round petrol-head Norm Handinge.

The outfit has been building one-off, specialist radiators for more than two decades and, according to Norm, there’s not really anything such as an off-the-shelf Aussie Desert Cooler radiator, because all his work is for custom installations, usually as a result of an engine transplant where an OE unit either won’t fit or won’t cope.

“We’re seeing a lot of blokes putting 6.2 and 6.5-litre GM turbo-diesel V8s in four-wheel drives these days,” says Norm, “along with people adding big aftermarket turbos or building vehicles to tow big loads. So all we do is heavy-duty. Typically, the stuff we build is around 30 per cent up on the OE core capacity.”

The big argument for the ages, of course, has been whether to use aluminium or a brass-copper core in a radiator for a rough-and-tumble gadget like a four-wheel drive. But Norm reckons it’s a bit of a no-brainer these days.

“We do both brass-copper and aluminium, but with four-wheel drives now, 99 per cent of the stuff we’re doing is aluminium. We’re just getting way better results.”

“We do both brass-copper and aluminium, but with four-wheel drives now, 99 per cent of the stuff we’re doing is aluminium. We’re just getting way better results.”

And that, says Norm, is all down to the superior heat transfer thanks in part to the fact that a radiator achieves its maximum heat transfer at the point where the tube joins the fin.

“That’s the critical area, and in a brass-copper radiator, you join the tube to the fin with solder. And solder is made of a lead-tin mixture, so you end up with an insulating layer of lead and tin right where you should be getting your maximum transfer.”

So what about the question of vibration (a typical scenario in a four-wheel drive operating in Australia) when crossing the inevitable corrugations?

“If a radiator is built properly with the right wall-thickness, you shouldn’t have a problem,” says Norm. “In fact, we even go to the trouble of adding gusseted corners in the core to eliminate another potential stress point. I reckon a lot of the other problems people have had over the years with aluminium cores is that a lot of shops don’t know how to repair them properly. You also have to use the right coolant. We specify the organic type used by GM or Toyota, and we don’t have problems at all.”

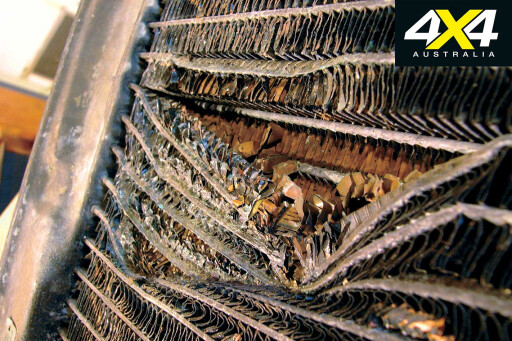

According to Norm, it’s often a case of user-ignorance, like the wrong coolant, that brings the vehicle’s original radiator undone.

According to Norm, it’s often a case of user-ignorance, like the wrong coolant, that brings the vehicle’s original radiator undone.

“The other thing that will result in tears is poor vehicle maintenance, particularly bad wiring where somebody has added equipment but not earthed it properly. When that happens, you get what’s called stray-current corrosion. Brass-copper radiators are less prone to stray-current corrosion, so if you’re the lazy type, maybe brass-copper would be better.”

Gold Coast-based PWR’s Dave Mawson reckons that stray-current issues are pretty much the only way to kill a PWR radiator these days. PWR uses alloy construction exclusively and while the company is best-known for its motorsport exploits (it supplies every NASCAR team and all but one Formula 1 team with cooling products, and has its own wind tunnel) it also has 10 or 15 four-wheel drive part numbers that are the hot sellers.

“Funnily enough, ” says Dave, “the majority of our radiator sales are to people with older vehicles; stuff like GQ and GU Patrol and 80 Series Land Cruisers. It’s the die-hard market. But it was put to me the other day that these older vehicles are kind of like forklift engines driving army tanks. And that’s pretty much right, so a reliable radiator with the right cooling capacity is an absolute necessity for these guys, because they’re the vehicles that are still getting used hard in the middle of nowhere.”

Dave’s main piece of advice (aside from avoiding the el cheapo online ‘bargain’) is to be sure to buy a radiator from somebody who knows what they’re talking about.

Dave’s main piece of advice (aside from avoiding the el cheapo online ‘bargain’) is to be sure to buy a radiator from somebody who knows what they’re talking about.

“Talk to the experts: What’s your application? How will you be using the vehicle? What’s your expectation? It’s a critical part of the puzzle. We often get blokes who want the biggest, thickest radiator they can buy. But then you discover that they’ll be running around at low speeds in low-range, at which point what they think they want is actually too big.”

So what about those bargain-basement rads? The radiator you should really give a wide berth to is the one that comes from an unknown supplier (often online and often from somewhere like China).

Hey, maybe you’ll get lucky; maybe you’ll be the Golden Child that buys a quality radiator from an online auction site at a too-good-to-be-true price. But more probably, you’ll get stuck with a heap of junk that fails spectacularly, miles from home and not only costs you a big recovery fee, but toasts your engine into the bargain. Your call…

What Ron says...

The elder statesman of this magazine, former editor Ron Moon, has never really been short on opinions. But unlike those of the armchair expert, Ron’s views are the result of having been there and done that. And when it comes to replacement radiators, Ron’s a bit leery of the alloy stuff.

The elder statesman of this magazine, former editor Ron Moon, has never really been short on opinions. But unlike those of the armchair expert, Ron’s views are the result of having been there and done that. And when it comes to replacement radiators, Ron’s a bit leery of the alloy stuff.

“A few years back, I had to replace a radiator in my truck, so I fitted an alloy unit from a reputable company,” Ron recalls. “But long before it should have failed, the mounting studs pulled through the bottom tank. As you can imagine, the water didn’t last too long at that point. To make it worse, I was somewhere up near the Somalian border in Kenya. So not ideal.”

Ron replaced that radiator with the best he could find in deepest, darkest Africa: another alloy unit.

“That lasted until somewhere in Mongolia when it failed, too. When we got back to Australia I went to a specialist place and asked for a one-off radiator that would do exactly what I wanted. Again, against my better judgment, I got talked into another alloy-core unit which lasted until the next trip north. When it failed in Townsville, I went to a radiator shop and asked for it to be repaired. But the bloke running the shop told me he could replace it with a copper unit or I could take my alloy piece of crap and drive to Rockhampton to find somebody to fix it. So now I have a copper-core radiator and it’s been faultless.”

“That lasted until somewhere in Mongolia when it failed, too. When we got back to Australia I went to a specialist place and asked for a one-off radiator that would do exactly what I wanted. Again, against my better judgment, I got talked into another alloy-core unit which lasted until the next trip north. When it failed in Townsville, I went to a radiator shop and asked for it to be repaired. But the bloke running the shop told me he could replace it with a copper unit or I could take my alloy piece of crap and drive to Rockhampton to find somebody to fix it. So now I have a copper-core radiator and it’s been faultless.”

“I reckon a lot of the blokes making alloy cores are using too-thin material to help with faster heat dissipation. Which is fine in a road car, but these thin alloys won’t cop being pounded over a thousand kays of corrugations. So it’s copper or nothing for me from here on in.”

COMMENTS