Australia’s car-manufacturing history is about much more than merely building Holdens and Fords.

Plenty of us forget that this Wide Brown Land previously built models for brands as diverse as Citroen, Datsun, and Jeep.

Here’s a round-up of a dozen of the lesser known models to roll out of Aussie factories.

Datsun 200B

AH, the Datsun 200B. As with all 12 cars featured here, it was produced back in the days when Australia actually made things, yet the 200B goes down in history as an example of what could go wrong when global vehicles had to be altered to meet the old local-content requirements.

The 200B was largely maligned because of the sedan’s locally produced live rear axle made by Borg Warner in Albury. It was fitted in lieu of the Japanese independent rear suspension that made the Datsun 1600 and 180B such awesome rally cars. In all my time at grassroots rallies, I haven’t seen a 200B rally car. People would laugh and then throw rocks.

The 200B launched at the end of 1977, but Wheels archives suggest the car was not a steaming turd. Early on, Datsun offered IRS on the sedan and coupe but the suspension was ill-sorted. Live-axle versions were introduced in late-78 to increase local content, and testers felt it was actually the better car by far.

Even so, Nissan told Wheels at the launch of the 1980 update that it had “tidied up the vehicle’s characteristics”, including vibration, suspension, steering and brakes.

Despite its imperfections, the dull but dependable 200B was a sales success and even led its class until the Sigma knocked it off at the end of the decade.

AUSSIE PRIDE

- The live-axle version handled better than most people think.

IT’S A SHAME

- One of the most boring cars Australia has ever produced.

Ford Mustang

FORD Australia’s most colourful managing director, American Bill Bourke, was always prepared to think outside the square. That’s why, when it came to launching the 1966 XR Falcon, Bourke thought it would be a good idea to import a batch of 400 Mustangs and convert them to right-hand drive for local sale.

Bourke’s idea was to have a Mustang in every Ford dealership, sitting next to an XR Falcon and a sign that read: “The Mustang-bred Falcon”. Ironically, the Mustang was originally based on the Falcon platform, making it a Falcon-bred Mustang.

An initial batch of 48 Mustangs arrived and were converted to right-hand drive at Ford Australia’s Homebush factory in Sydney. These 1965 models were snapped up by keen dealers. The company then brought in 113 of the 1966 models for conversion. The total number was well short of the initial plan because some dealers were not confident they could sell the car.

All the local Mustangs were equipped with the 289 cubic-inch (4.7-litre) V8, wore Australian ID plates and had small metal decals mounted to the door sills that identified them as Australian.

Ford Australia didn’t convert any other Mustangs itself, but it commissioned Ford Performance Vehicles (which it owned in partnership with Prodrive) to convert imported Mustangs to right-hook in 2001 and 2002. Only 377 were produced.

Fast-forward to the current era, and the new-generation Mustang, built as a factory RHD model in the US, of course, has been a smash hit for Ford Australia.

AUSSIE PRIDE

- Theseu00a0very rare converted Mustangsu00a0are worth a mint.

IT’S A SHAME

- Ford Australia only converted 161 of the classic machines.

Hillman Gazelle

YOU might recall that Holden was located on Salmon St, Fishermans Bend, in Port Melbourne, but another car maker used to build cars on the same street.

That company was Rootes Australia, the local arm of the British Rootes Group. After building a factory on the corner of Williamstown Rd and Salmon St in 1946, Rootes became one of the first British manufacturers to set up shop here.

Its Port Melbourne factory assembled Humber, Hillman, Sunbeam, Singer, Commer and Karrier vehicles from CKD kits shipped from England, though production kicked off with the Hillman Minx. Rootes later purchased a 35-hectare site near Dandenong with the intention of building a full-scale manufacturing plant, but the plan never eventuated.

In late 1965, Rootes Australia merged with Chrysler Australia, though Rootes assembly continued in Port Melbourne.

One of Rootes Australia’s more interesting models was the 1966-67 Hillman Gazelle. Mixing an upmarket Singer body and interior with a high-compression, alloy-headed 1725cc Sunbeam Rapier engine, the Hillman Gazelle was a unique Aussie variation on Rootes’ decade-old ‘Audax’ sedan. And it was easily the world’s best.

A robust 63kW gave the four-speed manual Gazelle almost 100mph (161km/h) performance, but it was simply a stop-gap measure before Hillman’s all-new Hunter launched in 1967.

Production ceased at the Port Melbourne plant in early 1973, burying the Hunter in lieu of Chrysler’s Adelaide-assembled Galant and forthcoming Centura.

AUSSIE PRIDE

- Upmarket version of the Minx, with genuine performance.

IT’S A SHAME

- Automatics were slugs; the design was from the mid-50s.

Willys Jeep

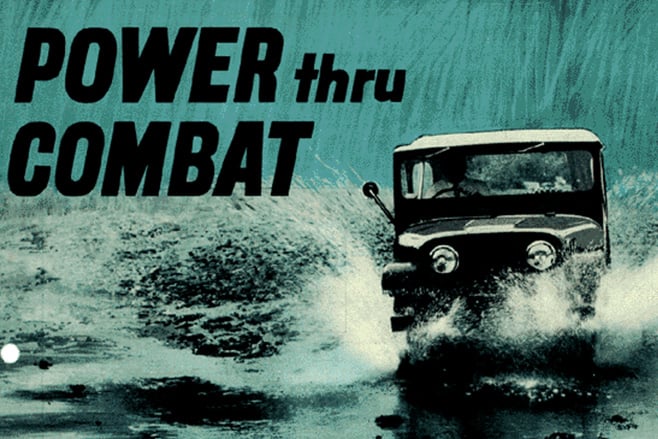

BACK in the 1960s, you could have a Geelong-made six-cylinder under the bonnet of your rugged Jeep, which was produced in Queensland for many years.

The basic Willys Jeep was developed at the tail end of WW2 with post-war administration in mind, thus the CJ designation, which stood for Civilian Jeep.

Some surplus army Jeeps came to Australia, but they were all left-hand drive. Only a few importers saw the appeal of the tough machine, brought them in and had them converted.

Then, in 1958, Kaiser Industries (which owned half of Willys) started producing the CJ3 Jeep at a plant in Brisbane. In 1965, it opened a new plant in Rocklea. Instead of importing the Buick V6 installed in US models, Jeep began fitting the Falcon’s straight-six, gearbox and pedal box to the longer-wheelbase CJ5 and CJ6 models.

This tie-up also led to Ford Australia purchasing the locally made Jeep chassis, which was used as a base for the peculiar XY 4×4 Falcon Ute.

The local Jeep producer started off with about 40 percent local content and aimed to reach 90 percent, but that wasn’t achieved before local production ceased in 1985, when the Australian dollar was floated. Jeep’s subsequent history as an importer was chequered until sales really took off under FCA’s Australian arm in around 2013.

AUSSIE PRIDE

- Go anywhere ability and Falcon grunt. Hurrah.

IT’S A SHAME

- Basic cars for basic folk and hard work to drive.

Renault 12

THE idea of Renaults and Peugeots being produced in the same factory is like pairing up Ford and Holden production, but it did happen right here in Australia. It came about because of Australian government policies aimed at growing the local car-manufacturing industry.

Continental & General assembled a range of vehicles including Peugeot, Citroen, NSU and Studebaker in the Melbourne suburb of Heidelberg West. In 1964, it was purchased by Renault and stopped producing everything else, except for Peugeot models; they continued to be built alongside Renaults in what was, as far as we know, the only place the two brands got into bed together.

Renault increased the number of locally sourced parts it used, in line with local content policy, reaching its peak with the Renault 12, the best known and most popular model the brand has sold in Australia.

It was launched in Europe with a 1289cc four-cylinder engine, but those local content regulations (it’s complicated) meant the capacity was dropped to 1251cc.

The Renault 12 won our 1970 Wheels Car of the Year award and was selling strongly, but controversy over French nuclear testing in the Pacific Islands in 1973 hurt the brand; sales dropped and unions even refused to unload ships with Renault parts.

Renault devoted some production space to building the Cortina wagon for Ford, but the operation was ultimately not viable and the French pulled up stumps in 1981.

AUSSIE PRIDE

- Looked good, had great seats and was economical.

IT’S A SHAME

- Renault was owned by the French government. Alors!

Volvo 200 Series

THE Holden Special Vehicles factory in Clayton, Victoria, didn’t always produce such powerful cars like the Clubsport, GTS, or more recently, Chevrolet Camaro. Back in the day, it was used to make (whisper it) Volvos.

The operation was called Motor Producers Ltd (previously Martin & King) and it began by assembling, then manufacturing, Volkswagen Beetles. As VW’s sales dwindled, production space was loaned to Nissan, then in 1972 a deal was signed to produce Volvos. Nissan took over the plant in 1977 and turned it into a full-scale manufacturing facility before shutting shop here in 1992.

Volvo recognised the potential of its car in Australia, and its local assembly operation ended up producing some 65,000 cars through to 1988.

It started with the 140 series and ended with the 760, but the 240 and 260 are best known to Australians. The big boxes were boring but safe and their customers earned a reputation as bad drivers who wore hats and were also desperately slow (leading to the infamous cry of “Bloody Volvo Drivers”).

The cars also had longevity on their side. Indeed, only five or so years ago, one Volvo Australia executive made a light-hearted suggestion that so many 240s remained on our roads that a bounty was needed for each one taken off in order to improve the brand’s image.

Finally, a fun fact: the second digit in the title refers to cylinders; the 240 had a four, the 260 a V6. Until 1982, the third digit referred to doors; the 245 was a wagon, the 244 a sedan. Then it became a zero.

AUSSIE PRIDE

- Solid, reliable and safer than many cars of its vintage.

IT’S A SHAME

- Itu2019s a box. Did they even have designers back then at Volvo?

Chrysler Royal

CHRYSLER is best known locally for its iconic 1960s and 70s cars, including the wondrous Charger, but it was building vehicles in Australia long before that. Adelaide’s T.J. Richards made its own bodies for Chrysler vehicles from 1922 until it was bought by Chrysler in 1951.

The new operation began by assembling American cars in Adelaide, but in an effort to remain ‘modern’ while trying to save its pennies, Chrysler decided to develop a local version.

What it did next was not far from Johnny Cash’s fictional song about an assembly worker stealing parts from Cadillacs he built over several years in order to assemble a car at home that he called a ’59-60-61-62 model.

To replace its dated Plymouth, Dodge and De Soto sedans, all of which were derived from the P24-series Plymouth of 1953, Chrysler Australia produced a single model called the Royal.

Launched in 1957, the Royal attempted to marry the ‘Forward Look’ styling of its dramatic US relatives to the frumpy centre section of the old 1953 Plymouth. Pronounced tailfins, a wraparound rear window and a full-width, forward-slant grille did their best to make the AP1 Royal look mod, only to be undermined by its carryover roof, doors, windscreen, bootlid, bumpers, interior and breathless 3.8-litre side-valve six.

The even chromier AP2 Royal of 1958 took the mis-match to a new level, stacking yet another tail fin on top of its existing one, but the final Royal – the 1960 AP3 – was much better, especially as a V8.

With stacked headlights, sharper fins, triple tail-lights and a cleaner grille, it was the car the Royal always should’ve been.

The arrival of Chrysler’s radical Valiant in 1962 buried the Royal six, leaving the V8 version to soldier on until 1964.

AUSSIE PRIDE

- Just look at those fins. And the AP3u2019s awesome tail-lights

IT’S A SHAME

- Too fat. Didnu2019t stop. Didnu2019t corner.

Volkswagen Beetle

MANY Australians don’t know that Volkswagen used to be a serious manufacturer in Oz.

Its factory in the Melbourne suburb of Clayton – later taken over by Nissan and (for now) the home of HSV – was a vast 365,000 square metres, and component suppliers including fellow Germans Bosch, VDO and Hella set up nearby in order to feed the plant. Volkswagen ceased production in 1977, while Nissan produced cars there until it also shut down its Australian production in 1992.

Examples of the German-made Beetle first arrived here in late 1953, featuring a 22kW 1131cc air-cooled flat-four, but in June 1954, Martin & King started assembling them in Clayton from imported CKD kits, complete with an upgraded 27kW 1192cc engine.

A shift in government policy encouraged car manufacturers to increase local content and by 1957 the Beetle was 51 percent Aussie. Volkswagen (Australasia) Pty Ltd was then formed and after some huge investment in the Clayton plant, VW began full local manufacture of the Beetle in 1959.

The following year, the Beetle became Australia’s second-best-selling car behind the FB Holden, and by 1965 it had reached 95 percent local content, but newer Japanese rivals had a crushing impact on Volkswagen sales. To survive, the factory reverted to CKD assembly in 1968 and began loaning production space to other manufacturers.

At its high point, VW’s factory had 40 presses and the largest aluminium and magnesium foundry in the country. The operation exported to New Zealand, New Guinea, Malaysia, Indonesia, Fiji, Western Samoa and the Solomon Islands.

AUSSIE PRIDE

- An iconic design that thrived in Australian conditions.

IT’S A SHAME

- By the late-60s, more modern rivals were outselling it.

Citroën ID Parisienne

ONE of the most beautiful cars of the last century was assembled right here in Australia.

The Citroen ID was a less complex version of the DS, a revolutionary car that stunned the automotive world when it was unveiled in 1955. Launched two years later, the ID lacked the DS’s trick steering, brakes and gear change, but it was still like something from another world.

Citroen originally sent ID kits from France to England, where they were assembled and then shipped to Australia. Then, in 1961, Continental & General signed a deal with Citroen to assemble the ID at its factory in the Melbourne suburb of Heidelberg West.

Most of the parts came directly from France, rather than through England, which led to the sophisticated ‘Parisienne’ tag being added to locally assembled cars. It did use some locally sourced components such as interior trim.

The ID might have been slightly dumbed down in order to make it more affordable than the expensive and luxurious DS, but it was still brimming with cutting-edge technology for the time. It shared the DS’s unique hydro-pneumatic suspension system that used hydraulic lines that filled small spheres on each corner of the car with gas.

Changing federal government policy encouraged companies to switch to full local manufacture, but that didn’t suit Citroen’s local assembly model. As a result, the last Australian ID was assembled in 1967 and the factory continued to make Renaults and Peugeots, so the smell of cheese remained.

AUSSIE PRIDE

- It was beautiful, practical and rode like a dream.

IT’S A SHAME

- Brakes, steering and suspension could all fail if the single belt came loose.

Chevrolet Bel Air

NOTHING says ‘America’ like a 1959 Chevrolet Impala or Bel Air with their wild fins and outrageous cat-eye tail-lights. However, the beautiful Bel Air, along with several other GM products, was also assembled by Holden in Australia.

Holden continued to import and assemble GM product after it introduced its own model in 1948, along with some Vauxhall models from Britain, and decided to make a bigger effort with the 1959 Chevrolet and Pontiac models, which represented a big step forward.

It wanted to offer a high-end luxury model at a reasonable price, and the Chevrolet product was perfect, so long as the company avoided high import duty by assembling it locally.

Holden sourced the parts from GM North America and the bodies were assembled and painted at its Woodville plant in South Australia. They were fitted with Holden-sourced interiors and coated in the same paint colours as their contemporary Holden siblings.

The bodies were then delivered to one of five Holden assembly lines dotted around Australia (Melbourne, Adelaide, Perth, Brisbane and Sydney) and mated to the chassis.

The 1959 Bel Air, with its four doors and thin central pillar, was the first car available here with a two-speed automatic transmission (which had been available in the US for nearly a decade) and ran a 3.9-litre Blue Flame in-line six. V8s came later.

AUSSIE PRIDE

- One of the most stylish American cars ever.

IT’S A SHAME

- Handling wasn’t good on its narrow-tracked chassis.

Mercedes-Benz 220S

FEW modern Mercedes-Benz owners could imagine the vaunted three-pointed-star brand built cars in a Melbourne factory that also assembled Toyotas and tractors, but it did. And it built 7500 of them.

With Canberra introducing heftier taxes for wholly imported cars in 1953, Mercedes decided to assemble its cars locally. It teamed up with Standard Motor Company, which was based in Port Melbourne and was making a living assembling British Standard and Triumph models.

Mercedes sent most of the parts from Germany in a kit, with the engine and gearbox bolted together, ready for assembly. Some local components were sourced, including interior trim, batteries and tyres.

The cars were painted in Melbourne, and customers could choose from blue, green and black, or three shades of grey. A grey Mercedes? Some things never change.

The old round-shape Ponton series (German for pontoon) was available with a choice of four-cylinder or six-cylinder engines. The upgraded 220S, which Victorian Premier Henry Bolte helped launch in 1959, was fitted with twin Solex carburettors so it cracked the 100hp-mark (75kW) and was also good for 100mph (161km/h).

Standard Motor Company (which changed its name to Australian Motor Industries in 1958 and ultimately morphed into Toyota Australia) also made money assembling Triumphs, Ramblers, Toyotas and even tractors. At its peak, it employed 1600 people.

Unable to meet higher government local-content quotas, Mercedes-Benz switched to full importation in 1965.

AUSSIE PRIDE

- Large and graceful prestige car made in Australia.

IT’S A SHAME

- Build quality wasnu2019t up to German standards.

Rambler Javelin

ONE of the rarest Australian-built muscle cars is the Javelin, from American Motors Corporation, a car best known for its exploits against the Mustangs and Camaros in the incredible US Trans-Am race series.

AMC produced kits in the US, shipped them to Port Melbourne and assembled them at the Australian Motor Industries factory not far from Holden’s headquarters. The Javelin and all other AMC models were sold here under the Rambler brand.

The Javelin coupe sold here for about $7500 in 1968, which was almost double the price of the XT Falcon GT and Holden Monaro GTS 327 at the time.

The top-shelf models ran a 343ci (5.6-litre) V8 engine hooked up to a three-speed automatic transmission.

AMI also produced the Rambler AMX, Hornet and Matador models – and one prototype of the Gremlin hatch, a quirky small hatch with a six-cylinder engine. This right-hand-drive car was recently shipped back to the US and fully restored by an American AMC fan.

The kits for Australia were produced at AMC’s Kenosha plant in Wisconsin, but certain parts were left out so they could be sourced locally in order to earn tax benefits under rules that encouraged local component production. They were painted in the US, which meant no unique Australian colour schemes. AMI sourced seat trim, carpet and a few other minor components from local suppliers.

Roughly 250 Javelins were built in Australia from 1968-72 and Rambler production at the Melbourne plant finished in 1978.

AUSSIE PRIDE

- Itu2019s a snorting two-dooru00a0V8 muscle car.

IT’S A SHAME

- It cost almost twice as much as a Monaro GTS.