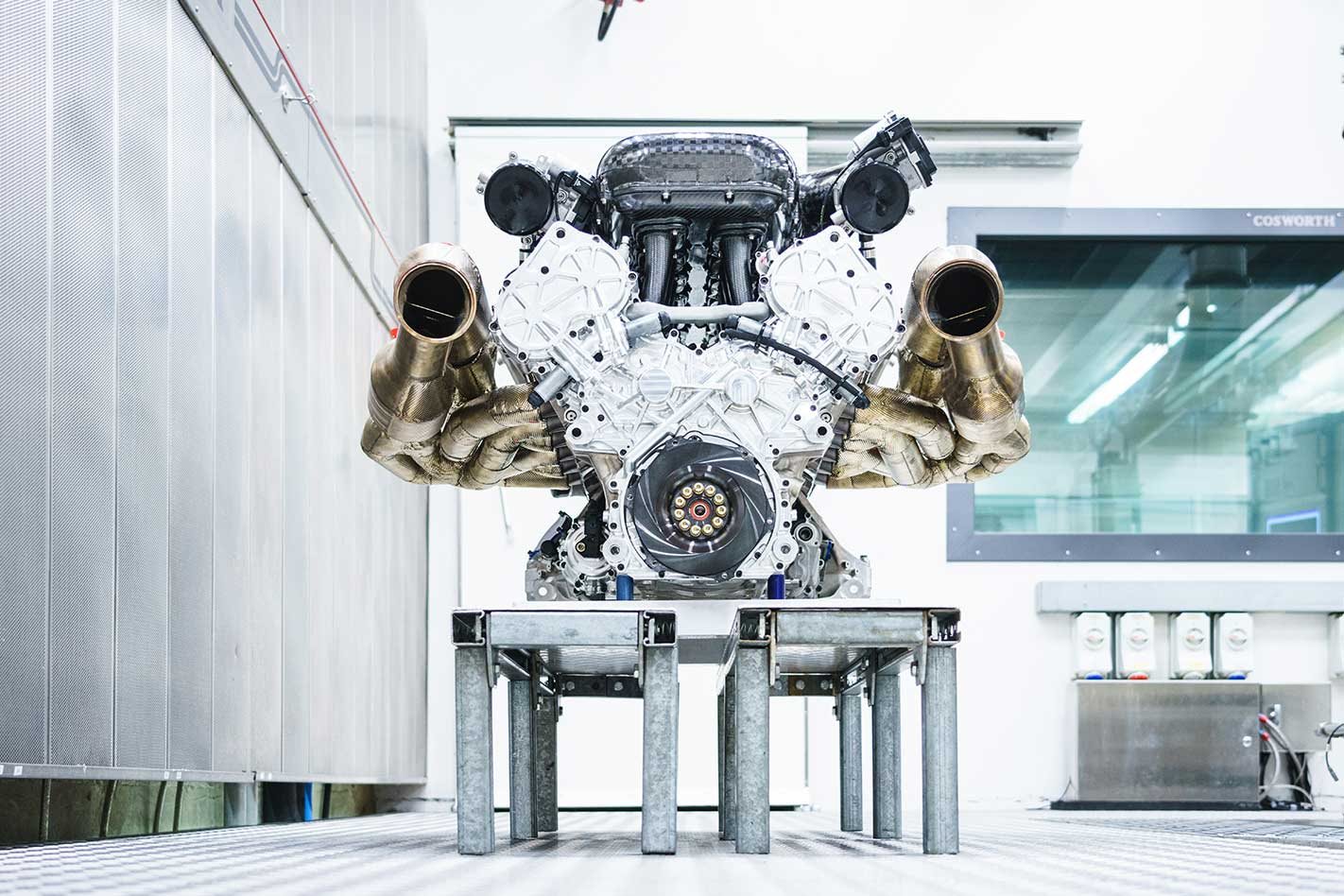

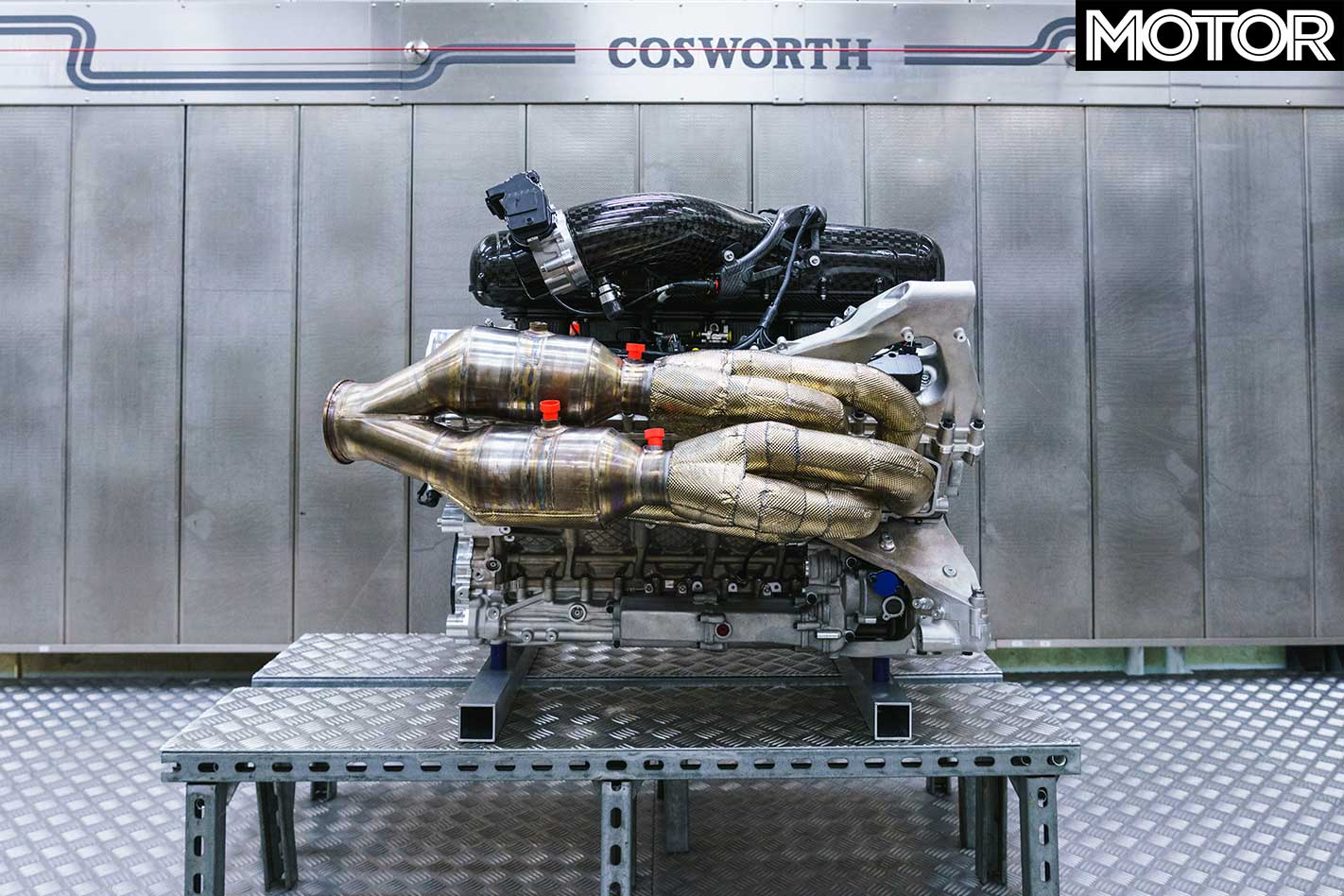

A maximum rpm figure north of ‘8000’ is unusual these days. Turbocharging has done away with the need for revvy motors, but it hasn’t removed the want. Proof of this comes in the form of an astonishing V12 engine built by Aston Martin, Red Bull’s F1 team, and most importantly, Cosworth.

Aston Martin revealed the Valkyrie’s hybrid output after this article was published in MOTOR’s March 2019 issue.

This triforce of engineering set out with the goal of creating “the ultimate expression of the internal combustion engine”. And it seems they’ve succeeded. With 11,100rpm marking its redline, the Valkyrie V12 has become a new benchmark for natural aspiration. The Valkyrie’s 6.5-litre heart is good for 735kW – which arrives at 10,500rpm – and 740Nm.

As Aston is yet to reveal details of the battery hybrid system which will accompany the ICE, the Valkyrie’s total outputs are still unknown to outsiders. Insiders, however, are incredibly excited about this engine.

“To anyone with a drop of petrol in their blood, a high-revving naturally aspirated V12 is the absolute pinnacle,” Aston CEO, Andy Palmer, said upon the reveal of this V12 marvel. “There was never any question that the Aston Martin Valkyrie would make do with anything less.”

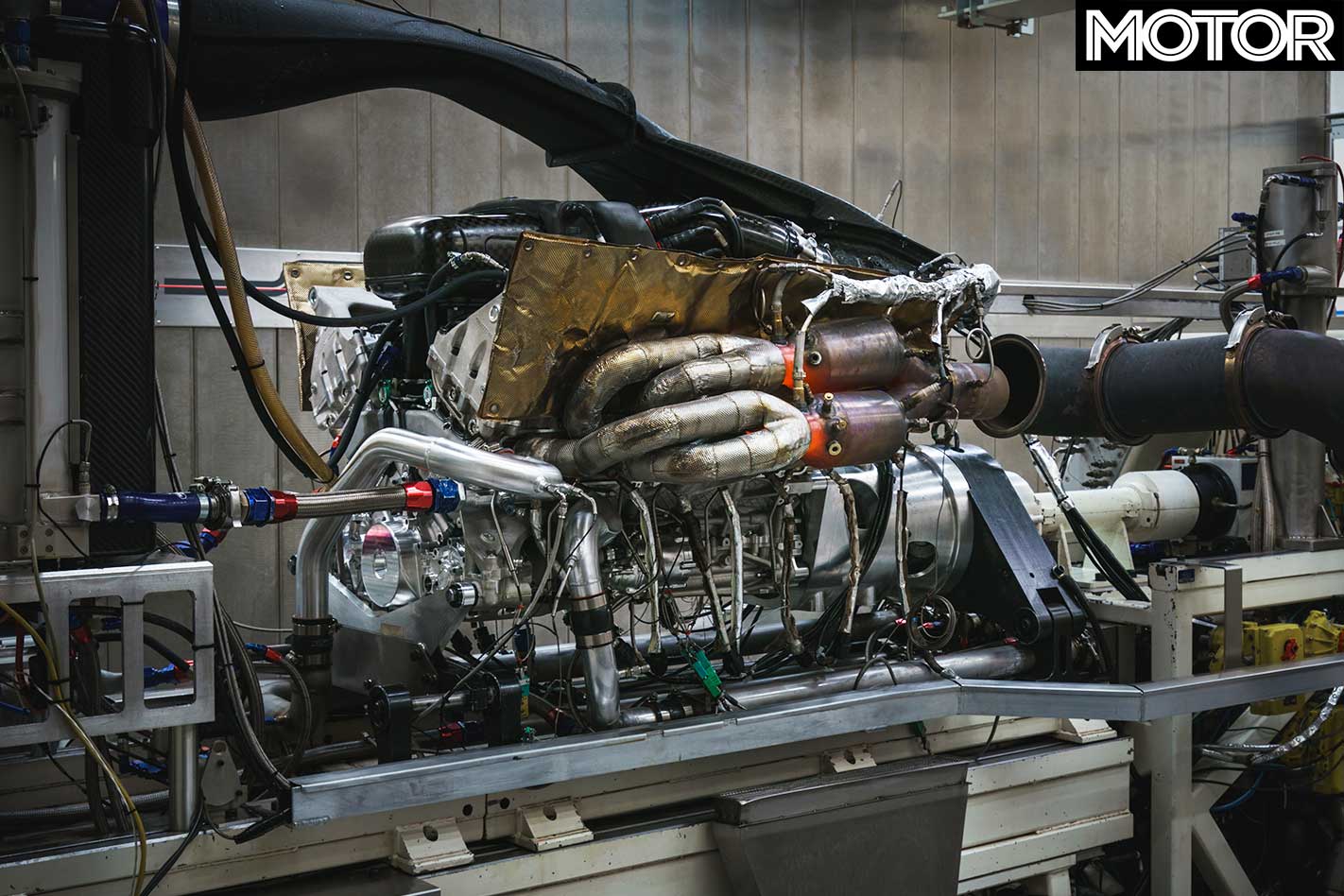

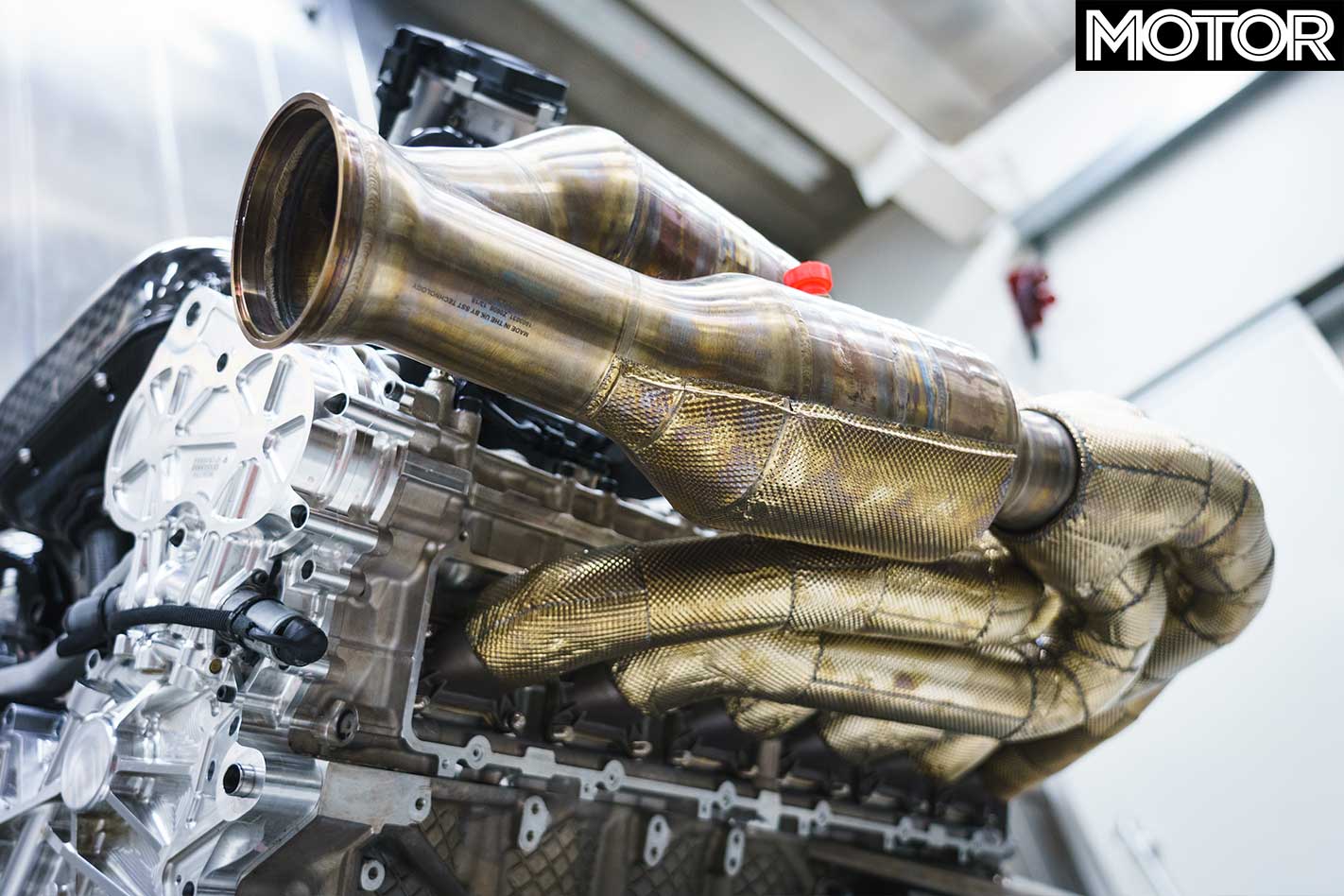

To reach its performance goals, Cosworth pulled out some of its motorsport experience and implemented it during the V12’s design and construction. For example, the engine boasts a lower per-litre weight figure than Cosworth’s last Formula One engine. The 3.0-litre race engines would weigh 210kg if scaled up to 6.5 litres. The Valkyrie’s V12 weighs 206kg.

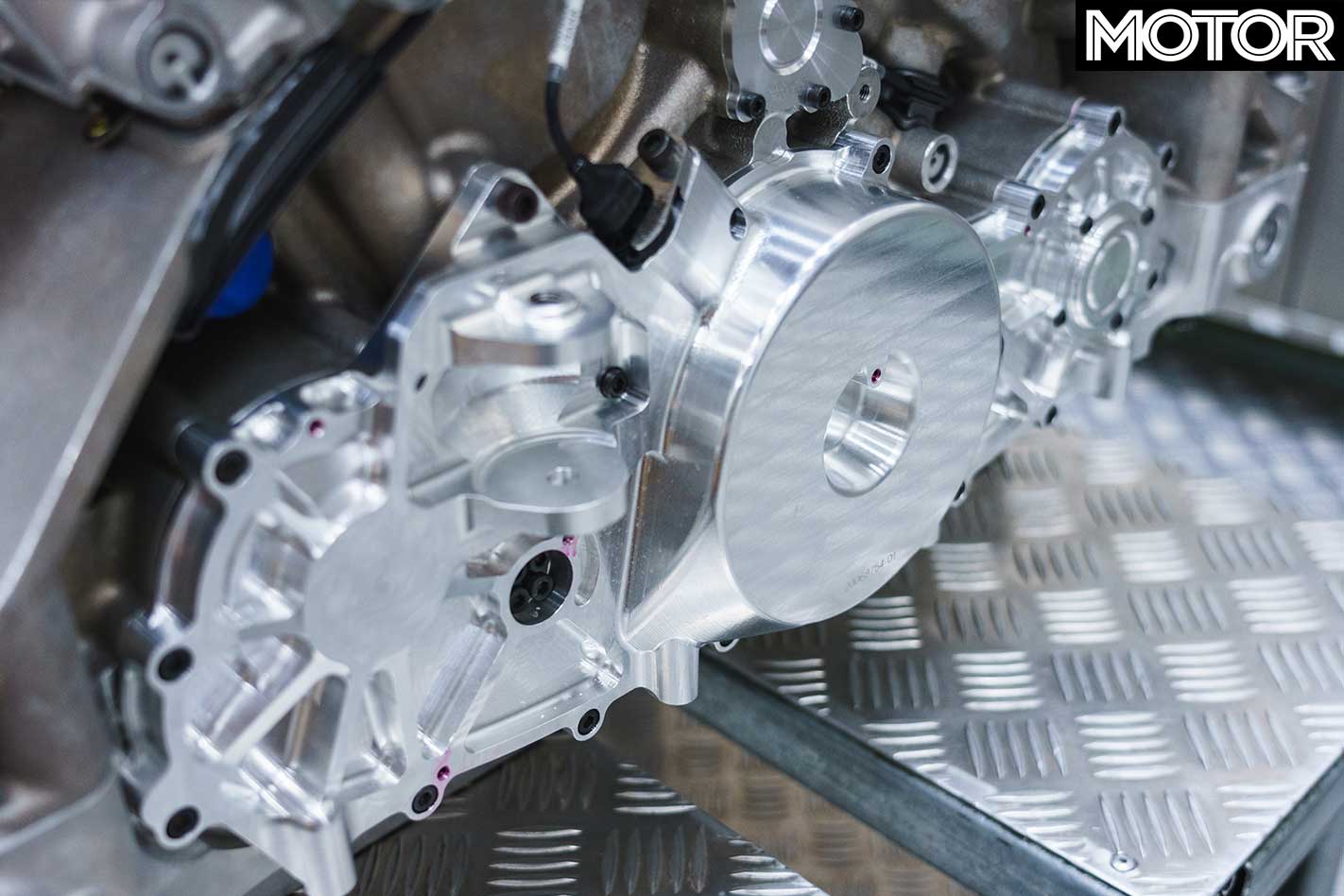

Keeping that weight down proved a “huge challenge” as Cosworth also avoided using lightweight alloys which have only been recently developed, as their long-term reliability is unproven. Most of the internal components of the engine are machined from solid materials such as titanium, used for the conrods and “F1-spec” pistons.

In another display of painstaking detail, Cosworth developed a billet crankshaft machined from a solid steel bar over six months, with approximately 80 per cent of the steel bar removed in that time.

As a result, the crank is about half as heavy as that used in Aston Martin’s 559kW One-77, a Cosworth-enhanced V12 itself, which had its time only a decade ago. When it first arrived, for a short while, the One-77 was the world’s most powerful naturally aspirated road car.

It seems rather fitting, then, that the accolade is once again to go to a V12-powered Aston Martin.

Valkyrie Cosworth V12 up close

Reaching the peak When the V12 was revealed to the public, Andy Palmer said Cosworth’s commitment to perfecting the engine was unwavering. “The result is a quite extraordinary engine, one which I doubt will ever be surpassed.”

Multitasking Aside from providing a plethora of power to the Valkyrie, the Cosworth V12 also acts as a “fully stressed element” of the hypercar’s layout. Without it, there is nothing connecting the front wheels to the back.

Challenge accepted Chief designer Adrian Newey set out many of the goals for the Valkyrie engine when approaching Cosworth, some of which the engine specialists said were “conflicting targets”. The result was the implementation of several processes unseen for a road-car development.