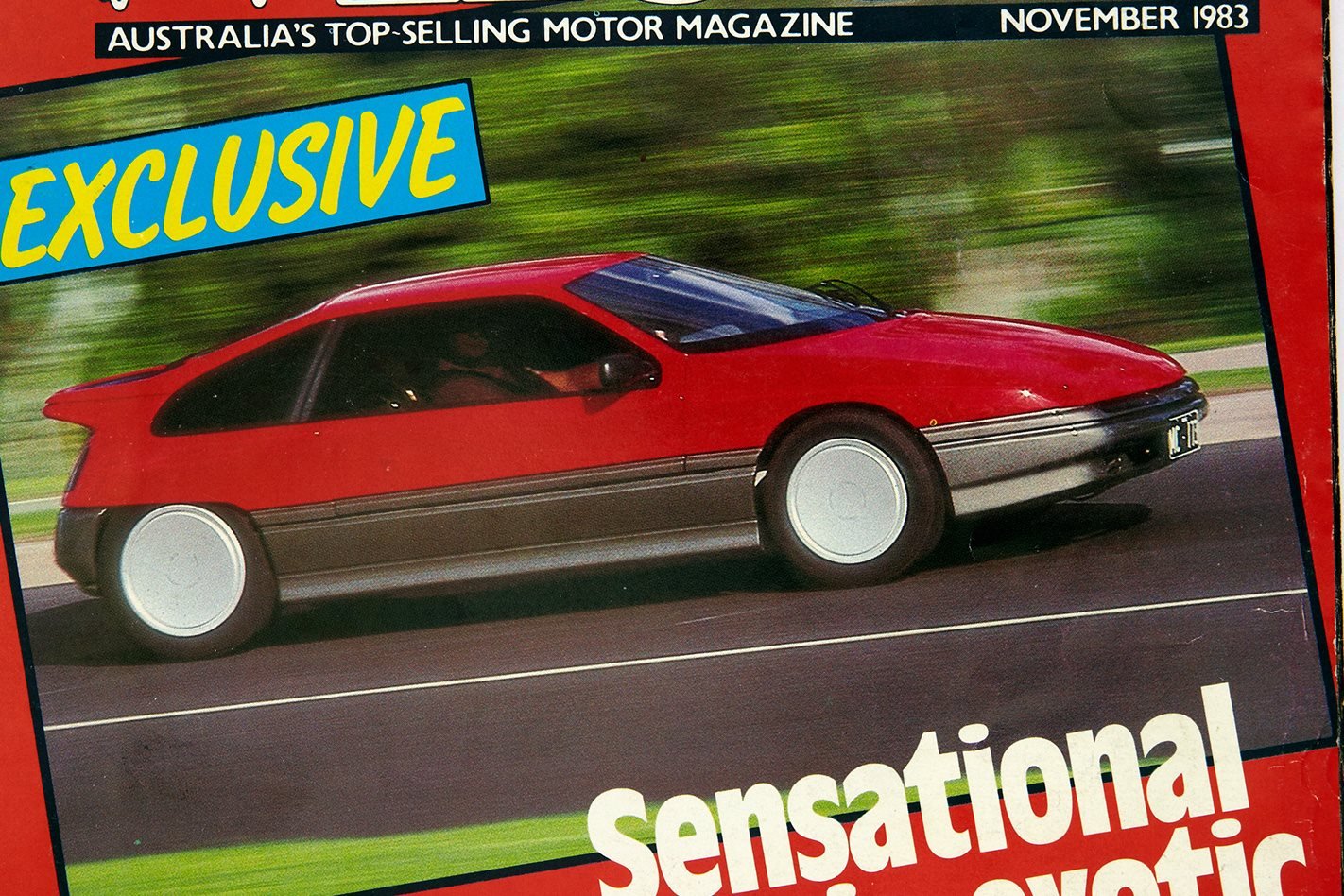

YOU’VE NEVER seen anything like it before, except in photos, perhaps from a European motor show.

First published in the November 1983 issue of Wheels Magazine, Australia’s most experienced and most trusted car magazine since 1953.

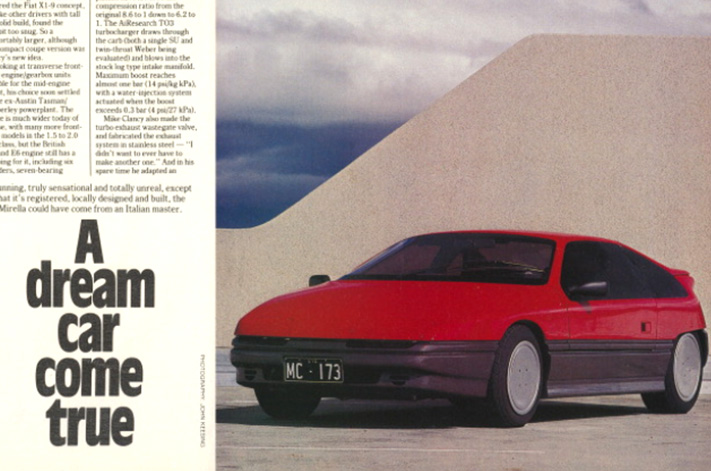

This is the Mirella 230TS, looking for all the world like a tomorrow car mock-up, the sort of thing the big makers and leading designers dream up to stir beholders’ imagination and interest. But their versions are usually just three-dimensional styling doodles, inanimate shells, all shape and no substance. And they’re designed for short, static lives in the styling studio or on the show stand.

To see the Mirella, just sitting out in the open at the roadside, comes as a shock to the senses. One’s first sight of the car triggers a jolt of raw disbelief. To hear it start, and to see it drive away, is something else again. Futuristic design exercise cars as we know them don’t do that … the Mirella does. And suddenly, as the tiny red wedge joins the traffic, you realise the Mirella isn’t a glimpse of the future. It is today’s car, here and now, with a stunning shape which, at one superb stroke, puts everything else behind the times.

From the several hours we spent with the Mirella, we know it catches attention, turns heads, opens mouths, races pulses and pops eyes like no other car.

“Unreal!” said the Porsche 944 owner who followed until we stopped. “Unreal!” sighed the 260Z girls as they parked in mid-road and ogles.

“Unreal!” said many others among the throngs who stopped and stared. It was the afternoon’s single most popular word. What that actually says of course, is that the Mirella is unreal because it is real, that it is extra-extraordinary because it is a proper car, for driving. It has to be. Enthusiast that he is, doctor Michael Clancy wouldn’t have it any other way.

Apart from an abiding interest in cars, Clancy is an incurable do-it-himselfer. The list of projects to which the 42-year-old Melbourne GP can lay claim includes a caravan with separate accommodations for the family hound and a mini beach buggy, a couple of earlier cars, and other self-made ventures too numerous for him to remember.

Most of Clancy’s self-built projects are mainly his own designs. Most are his own work, all are a credit to his workmanship. But all pale beside his latest venture. In the Mirella TS230 the good doctor has produced a simply stunning little coupe, without question the most striking and most professional road special ever made in Australia.

The Mirella TS230 earns top billing by setting yet higher standards in boldness of design and quality of execution. It’s a 100 per cent guaranteed mindblower … styled out of tomorrow, finished like something out of an elite Italian bodywork boutique, and performing like something straight off the racetrack.

It didn’t happen overnight. There was a lot more time and experience behind the project than the three years involved directly with the TS230. Strictly speaking, the new car is, for Mike Clancy, a logical extension of an activity which began when he was first bitten by the special-builder’s bug during the ’60s.

In 1966, more than a decade before the still-booming replicar craze got off the ground, Clancy built a pre-war Mercedes-Benz SS look-alike. In the best bitsa tradition, it wedded an early ohv Ford V8 to a Jaguar four-speed gearbox, installed in a Sunbeam Talbot 90 chassis with a Ford Customline rear axle and a Jaguar Mk IV front axle. The big roadster was provided with a suggestion of authenticity by a 1947 M-B 1700 grille, and exposed flexi-pipe exhausts added to its SS-style character.

The second car was begun in 1970 and reached the road only 20 months later. Although built in front-engine/rear-drive configuration, it was designed to allow relatively easy conversion to a four-wheel drive system. Clancy built the coupe’s semi-monocoque chassis which incorporated a full roll-over cage and accepted Austin 1800 front and rear sub-frames complete with Hydrolastic suspension, rack and pinion steering and four-wheel disc brakes. The car was initially powered by a Valiant 225 Slant Six engine, later by a Hemi265.

Clancy named the car after his wife, Mirella, and proceeded to use it for everyday transport, including three family-holiday trips from Melbourne to Queensland and back, towing a caravan. By the late ’70s the itch to build another more advanced and more specialised design was too strong to resist. He admired the Fiat X1-9 concept, but like other drivers with tall and solid build, found the cockpit too snug. So a comfortably larger, although still compact coupe version was Clancy’s new idea.

Looking at transverse front-drive engine/gearbox units suitable for the mid-engine layout, his choice soon settled on the ex-Austin Tasman/Kimberley powerplant. The choice is much wider today of course, with many more front-drive models in the 1.5 to 2.0 litre class, but the British Leyland E6 engine still has a lot going for it, including six cylinders, seven-bearing crankshaft, single overhead camshaft and 2.3-litre capacity.

About the only drawback is the four-speed gearbox – a five speeder would be nice – and the non-availability of alternative final drive ratios.

In stock form the single-carburettor E6 produced a claimed 76 kW at 5500 rpm and 157 Nm at 3500 rpm. With twin carbs the maxima increased to 85 kW and 160 Nm. Mike Clancy estimates his E6’s maximum power is about 150 kW thanks to his own-design turbo system. New pistons have lowered the compression ratio from the original 8.6 to 1 down to 6.2 to 1. The AiResearch T03 turbocharger draws through the carb (both a single SU and twin-throat Weber being evaluated) and blows into the stock log type intake manifold. Maximum boost reaches almost one bar (14 psi/kg kPa), with a water-injection system actuated when the boost exceeds 0.3 bar (4 psi/27 kPa).

Mike Clancy also made the turbo exhaust wastegate valve, and fabricated the exhaust system in stainless steel- “I didn’t want to ever have to make another one.” And in his spare time he adapted an airconditioning compressor at the front of the engine, replacing the alternator which was moved to the rear face. An oil cooler was also added. It had already been decided to use Datsun 240Z strut type rear suspension, and the Austin’s output flanges were drilled so the Datsun half-shafts could be bolted up to them. Because the Austin’s flanges were farther apart than the 240Z’s, and the chosen Globe “Bathurst” 14 x 7-inch alloy wheels had a bit more offset, rear track emerged at 1445 mm, an increase of about 100 mm over the Datsun.

For the front-end, Mike Clancy chose Toyota Mk II wishbones, uprights and hubs (same bolt pattern as the Datsun rear hubs), giving 1422 mm front track with 13 x 6-inch Bathursts. He also retained the Toyota’s disc front brakes and the Datsun finned rear drums. Rack and pinion steering came from a Peugeot 404, while the collapsible steering column and its switch stalks were BMW 633. The wheels were shod with Dunlop 60-series tyres, 205s front and 224s rear.

The remaining major parameter was the wheelbase, subsequently put at 2286 mm which, although compact for a mid-engine design, was determined by Clancy to be adequate to accommodate the cockpit and engine bay between the axle lines.

To help resolve the allocation of areas for the mechanical elements and occupants, and to clarify the chassis design, a scale model was made using lengths of three and six mm square balsa wood. This was subsequently translated into the full-size space frame, an elaborate, fully triangulated structure consisting of mostly square (some rectangular) tubing in 25, 38 and 50 mm sizes. To complete and further strengthen the chassis, thin steel panels were attached to the tubes to sheet-in the front and rear of the cockpit while giving a flat floor and fully boxed triangular-section side members which were then filled with expanding foam. Great resistance to intrusion in side impacts obviously rates very high in the doctor’s priorities.

Ahead of the cockpit toe board the unsheeted chassis tubes carry the suspension and steering while supporting the two radiators – a Morris Marina core for engine cooling and a Datsun 200B airconditioning condenser. The basic cockpit was completed with the gearshift rod (the only part beneath the flat floor), Volkswagen pedals, and a 63-litre fuel tank shielded from the cockpit in the inverted V between the vertical firewall and the seat backs. The fuel tank filler is housed in the offside B-pillar, behind the door, while the coolant filler is in the same location on the nearside.

While all this was going on, the body hasn’t been forgotten. In that department Mike Clancy collaborated with his brother-in-law, Clive Potter. A graduate of England’s renowned Royal College of Arts, Potter did a stint with Ford UK; then about 10 years ago came to Ford Australia where he is now Principal Designer, Interior. But his talent obviously isn’t limited to interiors only.

The initial thoughts of Clancy and Potter were towards a neat little notchback coupe. Determined partly by the mechanical elements, the packaging and the production (Citroen CX) windscreen, the notchback design was eye-catchingly modern if not mindboggingly dramatic. The pair was well satisfied with it in essence, however, and proceeded to make a quarter-scale model before commencing full size mock-up.

But even as the model was being finished, Potter continued developing the design on paper, taking the roofline and side windows to the tail in one smooth swoop, and adding a bold duck-tail to divide the rear-end into distinctly upper and lower sections. He converted his sketches into renderings and a large scale tape line drawing.

When they saw what they now had, they didn’t even hesitate. Mike Clancy remembers his excitement: “I told Clive that that was it. We wouldn’t bother making a model. I wanted to be making the real thing.”

In the traditional labourious way, the body mock-up was built directly over the chassis. Pieces of plywood were attached between the tubes, giving a solid if angular foundation. Next came a layer of sand and cement mixture to provide the raw outline, which was then covered in some places by plaster of paris, and in others by the special clay used by professional model makers. The surfaces were then painstakingly scraped, cut, filed, dragged and sanded to shape. In this hard, slow and necessarily demanding work, Clancy was also helped by Steve Park, another Ford design person glad to lend a hand on such an exciting project. Clancy is justifiably proud that the body is not only superbly finished but also immensely accurate … ‘at the very worst, to within a couple of millimetres or so”.

Early in this stage an Alfa G TV windscreen was added as the rear window, and as the mould took shape the detail work continued, including attention to ventilating the engine compartment. Air-entry slots were sculpted in the wing’s upper face, with air-exit slots under the wing between the special Clancy taillights.

The engine bay is isolated from the cockpit by a fixed window above the firewall. This may be double-glazed if noise proves a problem, although our run in the Mirella suggested the audio level is just about right to enthusiasts’ ears. There isn’t an engine cover as such, because Clancy wanted “the works” to be visible to onlookers. “Why hide a good-looking powerplant under a lid?”

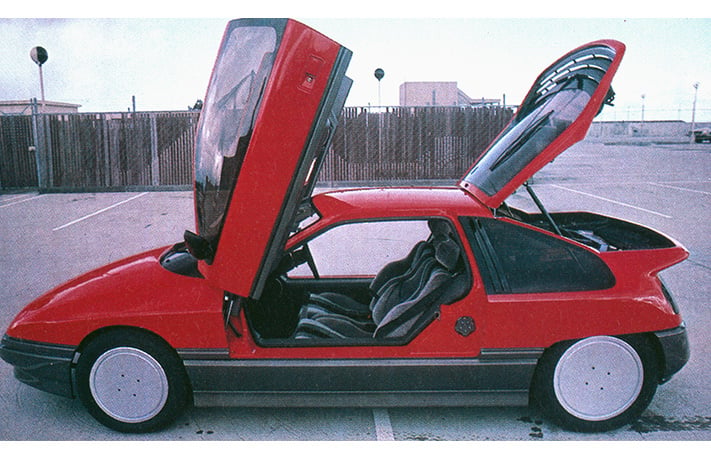

Making the overall mock-up was only a fraction of the job. It then remained to divide the mock-up into its major sections including the bonnet, rear hatch and doors. Early in the project Clancy had decided against either conventional or gull-wing doors. Instead he opted for a horizontal pivot on the A-post, so the doors would swing up and forward, a Ia Lamborghini Countach. The design avoids problems with close-parked cars, but you wonder about low-roofed places like garages.

The doors have to be opened to pay tolls, to say “Good morning Officer … “, and whatever else you usually lower the windows for. The Mirella’s side windows are fixed, which also explains the airconditioning. The side windows are darkly tinted acrylic, made on moulds taken from the master mock-up.

Inner skins were also moulded for the hatch, the doors and the cockpit roof. To facilitate working inside the roof, Clancy made a huge spit-like jig to turn the body upside down. Apart from the inner skin, the roof has upholstered panels either side of the National Panasonic overhead radio cassette console.

In all, no less than 14 separate fibreglass moulds were taken from the master mock-up and its related separate sections. The required fibre glass panels were then produced and assembled together for final finishing, although relatively little of that was required due to the exceptionally good quality of the mock-up and moulds.

The next step was to have the whole thing painted, and at that point Mike Clancy decided to step back and let a pro have a go. Thus the colour, a two-part enamel, was applied by Caress Panels, and it’s as good as the very best we’ve ever seen. In case you’re wondering about the bumpers, there aren’t any. In spite of the different colour and deep demarcation lines, the front and rear “bumpers” are integral with the nose and tail sections. The reasoning is that they are there to prevent chassis damage, and it would be easier to replace the nose and/or tail panels completely rather than design and make worthwhile separate bumpers.

The interior is furnished and finished with Scheel buckets, complimenting carpet and a Mono wheel. It will soon have some of the most advanced digital instrumentation ever to confront a driver. The main panel wasn’t ready when we were out in the car, but we saw and learned enough to have no doubts that this too will be extraordinary. There are, for instance, 12 warning lights and more than 100 LEDs, plus some fibre optics, and LCD readouts for the speedometer, tachometer and trip computer.

Clancy silk-screened the custom-made face, which will be night-lit by a special panel from the USA. It resembles a sheet of plastic with a mirror-like layer on one face. When a voltage is applied to the panel its entire surface is softly lit. Another nicety is the use of light-control films, also comparatively new to Oz. The film acts like a venetian blind in that you get clear vision only when you look between the slats. By covering the instrument panel with two layers of the film – one with the slats horizontal and the other with them vertical – the Mirella shouldn’t be troubled by external light affecting legibility of the LCD displays.

Such attention to detail is typical of the lengths Mike Clancy has gone to in making Mirella the car that it is. How much and how long? The cost of parts and services is put at about $10,000, which says nothing about the vast labour content. In terms of time, the project took three years solid, and was done in a workshop area about the size of a double garage.

He has no intention of producing another car. “This is it. The one and only.” He has done what he set out to do; build a car which is probably the best of its kind ever in Australia, and is in fact absolutely in world class according to local and overseas professional designers who’ve admired the Mirella’s lines, structure and finish.

Fast forward to 2017

Dr Michael Clancy, the enthusiast who created the mid-engine coupe, still owns the Mirella (now with around 30,000km on the odo). It’s still road registered, though at the moment not a runner. He’s currently slowly building a turbocharged Mazda 13B rotary engine to replace the 2.0-litre turbo Lancia Beta engine that now sits transversely behind the Mirella’s cockpit.